Manufacturers in the field of electronics are always looking for ways to reduce faulty units and increase throughput. The more efficient their facilities, the more profit that can be made, and the fewer materials are wasted.

The race for ultimate efficiency has led to the creation of a relatively new field known as manufacturing intelligence. The overall purpose behind manufacturing intelligence is to give greater control over costs and profits by making use of advanced electronics manufacturing software.

Today, we’re going to examine the tangible business benefits of embracing manufacturing intelligence, along with highlighting some core features that any manufacturing intelligence solution should contain.

The Benefits of Embracing Manufacturing Intelligence

Manufacturers should consider software and electronic manufacturing tools that provide machine intelligence as necessary. Businesses that currently reap the rewards of manufacturing intelligence will likely soar past those that have not yet adopted this new technology.

Some of the notable benefits that businesses can expect once they’ve embraced manufacturing intelligence are:

- Data-driven decision-making: When you consider the traditional way a decision is made, how much data is typically involved? While sometimes decisions can be informed by data, more often than not, managers are making decisions based on their own experiences. Using manufacturing analysis software that provides manufacturing intelligence will generate data-driven insights that can be used to streamline the decision-making process.

- Faster response times from problem to solution: You can’t always walk down the hall and ask someone a question these days. The supplier might be on another continent, and the facility experiencing issues might be hundreds of miles away. With the increasingly distant global operations that many companies have these days, fast response times can be difficult. Fortunately, predictive analysis in manufacturing streamlines a technician’s work, since it will provide them with a large amount of data and plenty of insights to work from. In fact, this is one of the vital predictive analytics use cases in manufacturing.

- Provide full traceability in electronics manufacturing: Traceability is important when a faulty unit is shipped and returned. Being able to trace back the issue to the source is essential to ensuring that no more faulty units are shipped. Manufacturing analytics software should be able to allow technicians and engineers to trace back an issue effectively.

There are more benefits that come with manufacturing intelligence than we’ll list here, such as streamlining process optimization manufacturing and increasing the first-pass yield.

Core Features of Manufacturing Intelligence Solutions

We can discuss benefits all day, but without the appropriate manufacturing intelligence solutions, your facilities will fail to reach any of these benefits. As such, let’s discuss the core components and features that make up an ideal manufacturing intelligence solution.

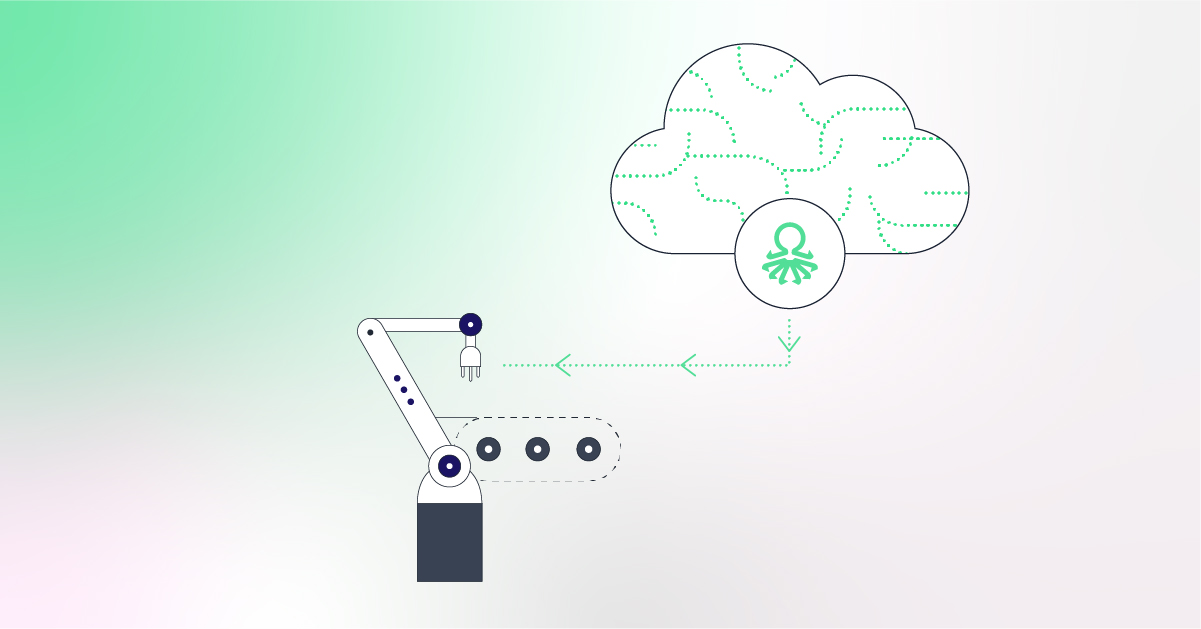

The method of distribution, both for software and firmware, is an essential factor to investigate. An ideal solution will allow technicians to easily check that both software and firmware of the machines are up to date. It could be quite expensive to send through 500 units and then realize that the wrong firmware is being used. This is one reason why manufacturing production optimization is of the utmost importance.

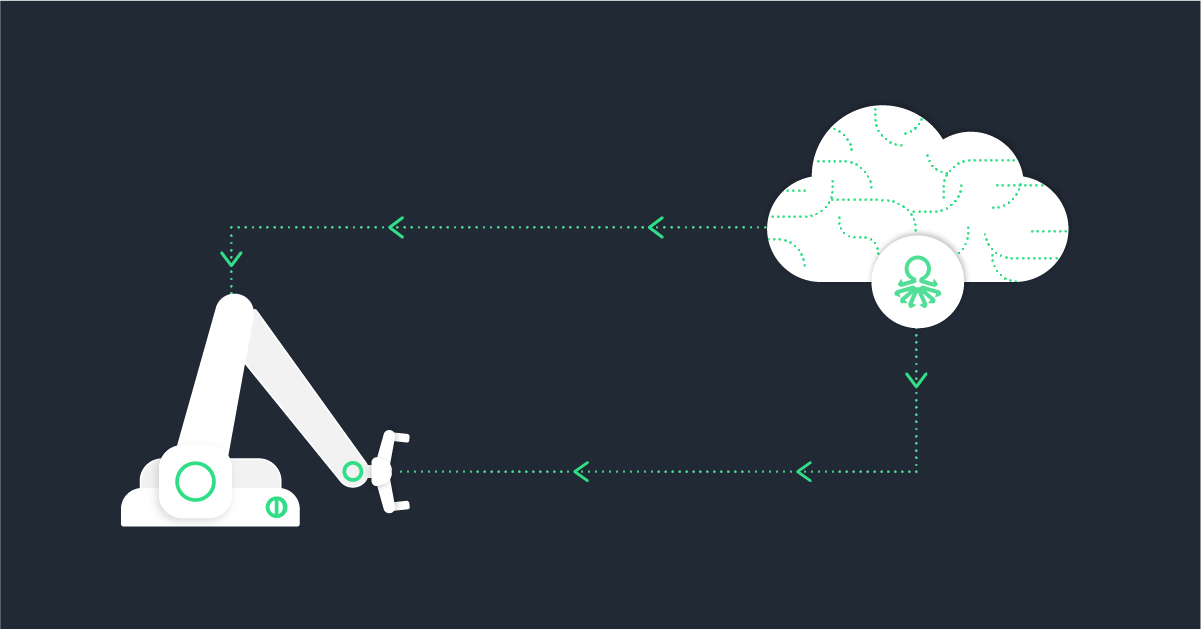

Perhaps the most important feature of a manufacturing intelligence solution is its ability to provide automated feedback from a specified trigger or notification. It’s impossible to think that someone will ever be in complete control over every step in the manufacturing process. Instead of aiming for such control, use a manufacturing intelligence solution that has the ability to respond to triggers and notifications, then react accordingly.

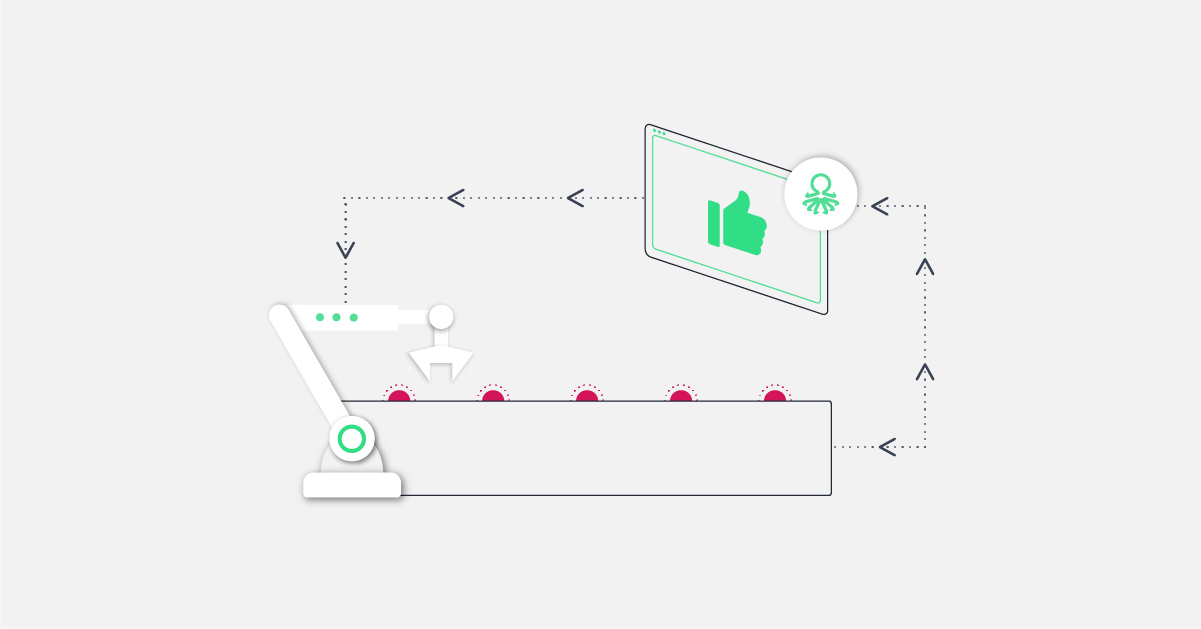

For example, you may wish to remove a faulty unit from production at a specified point. An ideal manufacturing intelligence solution will empower you to detect fault units once they are created and have them removed from the entire production line. This example shows how quality control methods in electronics manufacturing can be revolutionized with manufacturing intelligence.

Is Your Facility Embracing Manufacturing Intelligence?

Many electronics manufacturers have embraced manufacturing intelligence in one way or another. Those who lean into manufacturing intelligence and start using a reputable solution will likely come out ahead of their competition that fails to adopt this new technology.

Are you looking to embrace manufacturing intelligence? Get in touch with Vanti today to see how you can use predictive analytics to transform your production lines.