When you’re trying to achieve a reliable, consistent product and optimize production at the same time, defects can be your worst nightmare. But too many organizations find themselves facing a trade-off: Quality control and inspection can negatively impact cycle time.

It’s a non-stop juggling act: How can you speed up manufacturing without sacrificing quality?

Everyone’s talking about AI these days and how it can help you automate almost every aspect of your life. In some ways, AI is the obvious answer: It’s on the job 24/7, working faster and scaling better than human processes. But getting there can be a challenge. Do you have the knowledge you need to ensure that your automation project will be successful?

Let’s look at the biggest challenges when it comes to implementing AI and automation for defect detection. Then, we’ll explore the best way to make sure your investment in automated defect detection actually gets your organization where you need to go.

What’s Wrong with Human Defect Detection?

Many manufacturers haven’t yet made the move to AI and automation. That means they’re still relying on manual inspection processes. But as you probably know, there’s so much that can go wrong when you rely on manual testing…

- Employees can have an “off day,” becoming distracted and failing to catch defects.

- Employees call in sick, leaving you scrambling to find someone else who knows the product.

- Employees miss smaller, less obvious, or hidden defects that technology might catch.

Quality testers need specialized training and knowledge concentration, creating a bottleneck for your business. And once you’ve invested in that person and they’ve built up a base of expertise on your products, they might not even stick around.

Another issue is that human employees don’t scale. If you have two production lines, you need two trained quality testers, and so on. You could move testers from one line to another, but that means they can’t test as thoroughly or as often.

Finally, quality testers can only be in one place (like all of us!). Usually, that means they’ll be testing finished products only at the end of the production line. Most of the time, this means they won’t catch defects until it’s much too late—with all the material waste that goes along with that.

Why Introduce Automation and AI?

There’s a lot that can go wrong during production, and you need to know as soon as possible. That means speeding up the feedback loop—somehow. And that’s where AI comes in.

Human quality testers are an important part of your team, but they can’t be everywhere and they often can’t catch problems during production, where it could save you more money. AI promises an easier alternative—in place of and as a complement to human inspection.

It’s easy to see the benefits of AI and automation:

- They’re on the job 24/7.

- They detect defects outside the range of human vision (e.g., x-ray, microscopic).

- They can multiply and scale easily to multiple production lines.

So why aren’t all manufacturers using automation already?

The truth is that up until now, automating defect detection hasn’t always been easy. In fact, it’s often simpler and more affordable to just hire more human employees. Which is why many businesses end up sticking with inferior manual solutions years after more efficient alternatives become available.

Why Is Automation So Hard?

What makes it so difficult to automate defect detection? As much as we’ve all heard about incredible new uses for AI these days—it can do everything from ordering your groceries to guarding your home—it’s not as simple as it sounds.

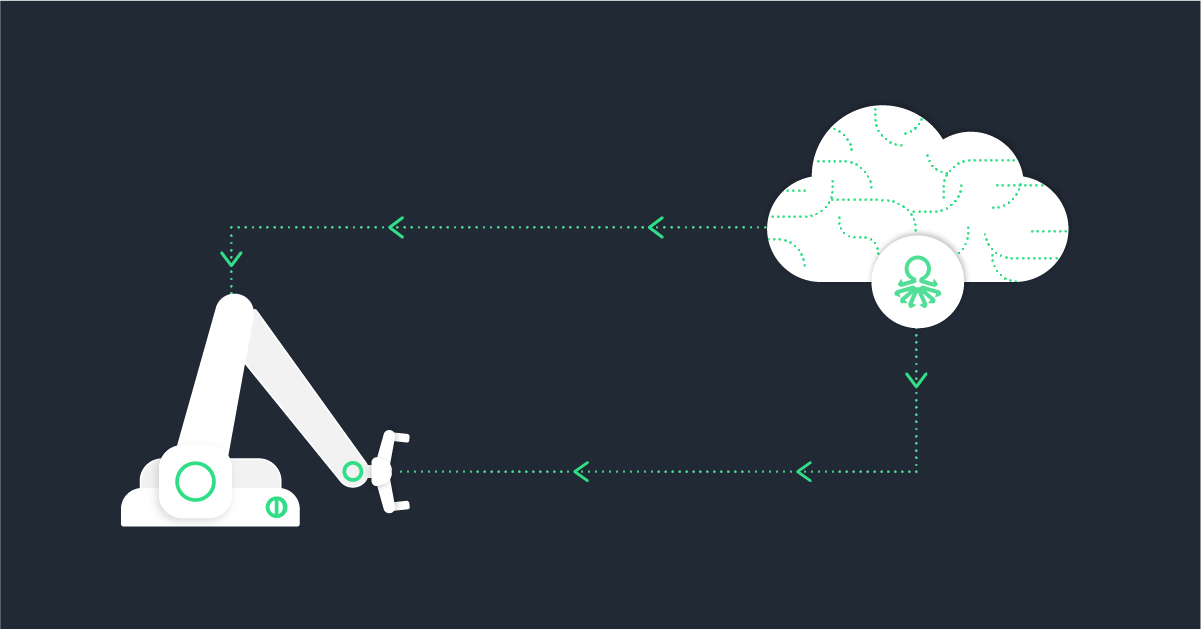

The main reason for this is that AI isn’t “born” intelligent: You must engineer its intelligence from the ground up, in three basic stages:

- First, there’s the “model,” usually created by specialized data scientists.

- Then, you still need to train the model, just like an employee (but harder!).

- Finally, you can put the model to work on an actual production line.

This work is typically done by data engineers, who create the model and then train it, usually by providing it with a massive number of images or other data (like temperature readings, audio, video, or anything else that can be measured) and letting it know what is acceptable and unacceptable (your margin of error).

(Of course, you first need to collect the data, but that part is relatively easy.)

Only once those elements are in place can the AI produce insights, catching defects before they reach customers and saving you money. And given the need for specialized research and development simply to create the model and get it running in production, most companies spend quite a lot of money just getting to this point.

Which is basically why more companies aren’t using AI and automation already. When your margins are narrow, you need to know exactly when you’ll start seeing ROI—ideally, from day one.

What Happens when the Model Breaks?

But there’s one more twist to the story. Remember the three-step process we explored above for getting AI and machine learning defect detection into production? Create the model, then train it, and finally implement it in production.

Unfortunately, even once you have your AI set up and producing insights, it’s not going to run forever.

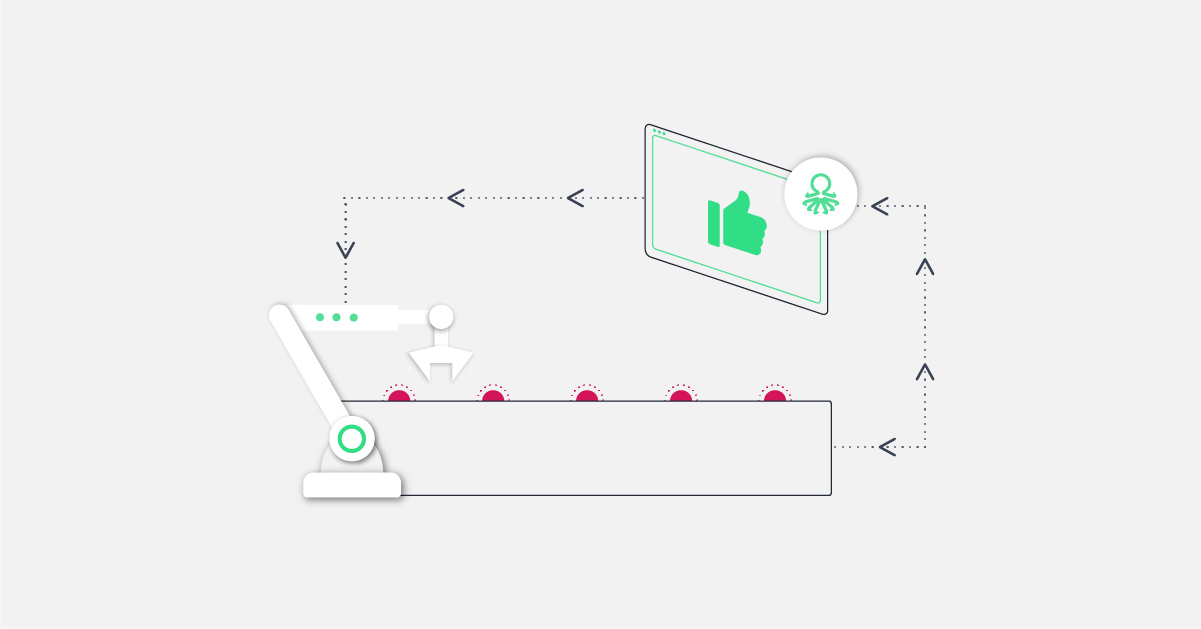

Eventually, the model’s responses will degrade. At that point, it may start reporting either false positives (flagging something as defective when it’s fine) or false negatives (failing to flag an actual defect).

Why do models fail?

- Concept drift – meaning that the original model doesn’t apply, like if you’ve changed the product specifications or when components further up the supply chain have been modified (also known as model drift)

- Data drift – meaning that the samples being tested are changing, for instance, due to a change of ingredients if you’re in the baking business

No matter how great the model is, it will fail. And once that happens, your team has to go back to the drawing board: either retrain the existing model on new data or prepare a brand-new model. This impacts your productivity and quality control and, of course, there’s the added cost for R&D to create a new model.

Either of these factors—or a degraded model that isn’t detected and kept in use—could severely impact your business, presenting major barriers to defect detection efficiency.

Fortunately, there’s a simpler way.

An Easier Path to Automation

Although implementing AI and automation in manufacturing hasn’t always been easy, they really do represent the future of manufacturing defect detection. There are simply too many advantages to give up on its potential—especially now that there’s an easier way to implement AI and automation in manufacturing production.

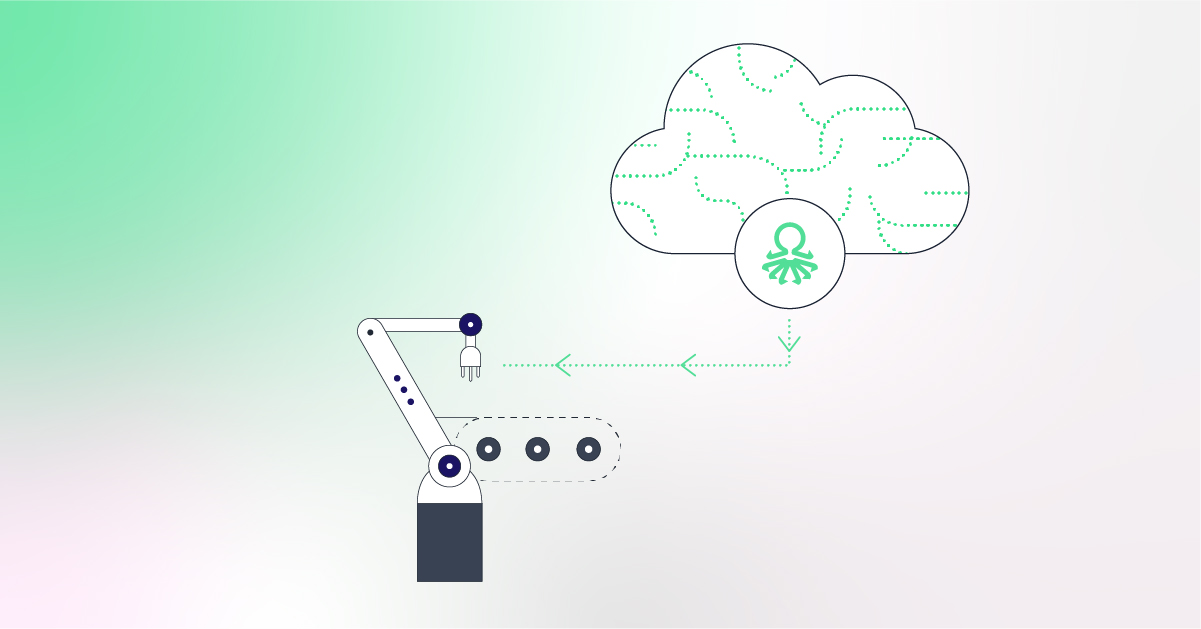

Vanti’s adaptive AI defect detection solution gives you a simpler path to automation. Adaptive AI works proactively: Instead of waiting for the model to break, it’s continuously optimizing. This solves the problem of drift and model breakage.

Vanti works behind the scenes, testing its predictions against your real-time data and finding new models that work better for defect detection. And when Vanti does find a better model, you can swap it out automatically, making it easy to implement AI that won’t drift or break.

- Nothing extra for you and your team to do

- No R&D, so you keep a lid on costs (no need to keep a data engineer on board!)

- Minimizes downtime from model failure or model replacement

You’ll start seeing other benefits as well. With data coming from your production line in real time (such as defect rate, equipment availability, uptime or downtime, overall equipment efficiency, operator performance, and more), you can optimize in other ways, accelerating production and achieving even greater cycle time reduction. And AI and analytics go where you can’t, letting you achieve the best possible quality.

Vanti’s adaptive AI has been created to eliminate barriers and put automation within reach of ordinary manufacturers. You’ll cut analysis time for your process engineers and create realistic optimization targets.

When you automate defect detection with Vanti, you’ll achieve greater cycle time reduction without compromising on quality—all with zero hassle, R&D, and downtime.

Click here to find out more and set up a no-obligation demo to see how you can get AI up and running in your manufacturing business in under 60 seconds.