AI-Powered Visual Defect Detection

Adaptive AI driving the Next-Generation of Visual Inspection Solutions

Vanti Visual Defect Detection is an AI-powered visual inspection solution that improves quality and efficiency in the manufacturing industry.

It uses adaptive AI to monitor and adapt to changes in the manufacturing environment. It also supports unsupervised learning for the classification of defect types and the discovery of new types.

The solution can be easily implemented in a matter of days, and offers real-time deployment options on-premises or in the cloud. It enables high-volume production lines to utilize AI for identifying sub-quality products.

Key Features

Deployment

Visual Inspection Challenges

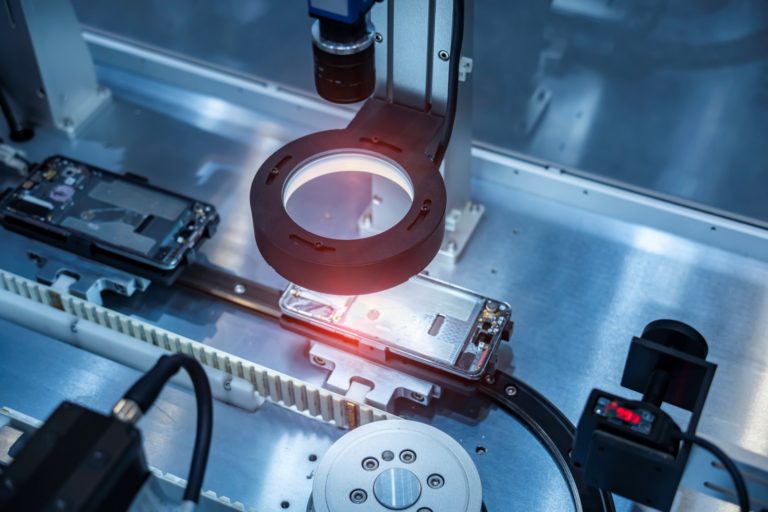

Efficient and accurate visual inspection is crucial for maintaining product quality and production schedules in the manufacturing industry.

However, manual inspection methods fall short in meeting these needs:

- Manual visual inspection is time-consuming and prone to human error

- High volume production can make manual inspection methods impractical

- Some defects, such as paint defects, are difficult for the human eye to detect

New, AI-based visual inspection solutions still face significant challenges, such as:

- Manufacturing dynamics cause data drift, breaking AI models

- Manual labeling is time-consuming and leads to inaccurate models

- Long model development and training times impede scalability

Vanti’s Adaptive AI-based Visual Defect Detection Solution

Vanti is a cloud-based manufacturing optimization solution that includes built-in AI-driven applications. One of these applications is Visual Defect Detection.

Any manufacturing professional can use Vanti’s platform to upload data, train a model and deploy a solution within days.

- Designed For Manufacturing Professionals: Vanti’s No-Code Platform was designed for manufacturing professionals, enabling them to utilize the power of AI without Data Science or programming expertise

- Real-time, high-volume Detection: Vanti’s Visual Defect Detection can detect defects and anomalies in sub-seconds, enabling highvolume production lines to utilize AI to scrap sub-quality products

- Self-adaptive, self-healing AI: Vant's AI is constantly monitors and adapt to changes in the environment that cause data drift, such as lighting variations, camera miscalibration, and fluctuation in production rates.

- No Labeling Required: Most AI-based solutions require data to be labeled before model training, which can be labor-intensive and may not support unknown defects or a wide range of defects. Vanti's AI, on the other hand, supports unsupervised learning, which automatically groups results into clusters, allowing manufacturing experts to classify defect types and discover new types of defects and anomalies.

- Any Camera, Still & Video: Vanti supports practically any camera that can produce consistent images in the required resolution for the application. Video or still images are both supported.

- Rapid Deployment: Vanti can be easily implemented by OT professionals in a matter of days, thanks to its user-friendly interface, data connectors, and underlying automation

- Cloud or Edge: Vanti is cloud-based, allowing users to train and develop solutions from any location. It also offers the option of real-time deployment on-premises.

Sample Use Cases

Automotive Paint Inspection:

Reduce manual labor by 50%

In the automotive paint process, small and hard-to detect defects are common. Vanti’s technology, in conjunction with cameras that scan the vehicle, automatically locates and categorizes defects around the vehicle, providing operators with a “defect map” to help them address the issues, saving the manufacturers time and money.

Predictive Quality in Electronics:

Increase efficiency by 5%

The manual assembly of electronics products is prone to errors, and issues are typically only detected at the end of the production line.

Vanti’s AI allows manufacturers to identify issues mid-production, saving significant resources and time, and improving throughput and product quality.

High-Volume CPG Inspection:

Increase throuput by 4%

In the consumer packaged goods industry, products are produced at a rapid rate. Vanti’s AI can detect issues with packaging or filling in real-time and when integrated with a sorting unit, can remove sub-quality items, increasing the overall quality and reducing inspection resources.

Vanti’s 3-Step Deployment Process

Setup: Vanti is compatible with a wide range of cameras, including still and video cameras. If a camera is already in place, Vanti can utilize existing images. In cases where new cameras or automation equipment need to be installed, Vanti works with its ecosystem partners to provide an all-inclusive solution.

Images upload: The user needs to have access to the images produced by the camera, and upload them into Vanti either from a computer or using one of Vanti’s connectors to AWS S3, Azure, etc.

Selecting Supervised or Unsupervised: Vanti supports both a supervised approach in which the user labels images as “good”, “bad” etc., or an unsupervised approach in which Vanti will cluster the images into clusters, enabling the user to process images that contain unknown issues

Training: With a click of a button, a new AI model is trained, normally in under 15

minutes, and the model predictions and model accuracy are displayed. If the results are not adequate, more images are uploaded and the model is retained until the required accuracy achieved.

Deployment: Using Vanti’s API, and optional edge deployment capability, a real-time stream of images is sent to Vanti, and a real-time stream of “predictions”, i.e. “good” or “bad” is provided. The prediction stream can be fed directly into a sorting arm, or viewed by an operator for further analysis and decision-making.