How is AI used in manufacturing? Today, we will explore how AI is setting up the manufacturing industry for a massive overhaul. We’ll examine several ways that AI has already improved the industry, along with what the future holds.

The manufacturing industry has been one of the most receptive sectors to artificial intelligence and machine learning.

But why have manufacturers, and specifically electronics manufacturers, been at the forefront of AI adoption?

There’s plenty of value in adopting AI for electronic manufacturing. A recent study found that the value of AI in the manufacturing industry is expected to surpass $16.7 billion by 2026.

Without a doubt, AI is the key to the future of electronics manufacturing, and early adopters will reap the rewards when it comes to process optimization, cost savings, and generating new insights.

So, How is AI used in manufacturing? Today, we will explore how AI is setting up the manufacturing industry for a massive overhaul. We’ll examine several ways that AI has already improved the industry, along with what the future holds.

AI Solutions for Manufacturing Increase Productivity

The top goals on many organizations’ list are boosting productivity while simultaneously reducing the cost of production. A study by Infosys found that the majority of respondents (66%) stated that increasing productivity via automation was high on their agenda.

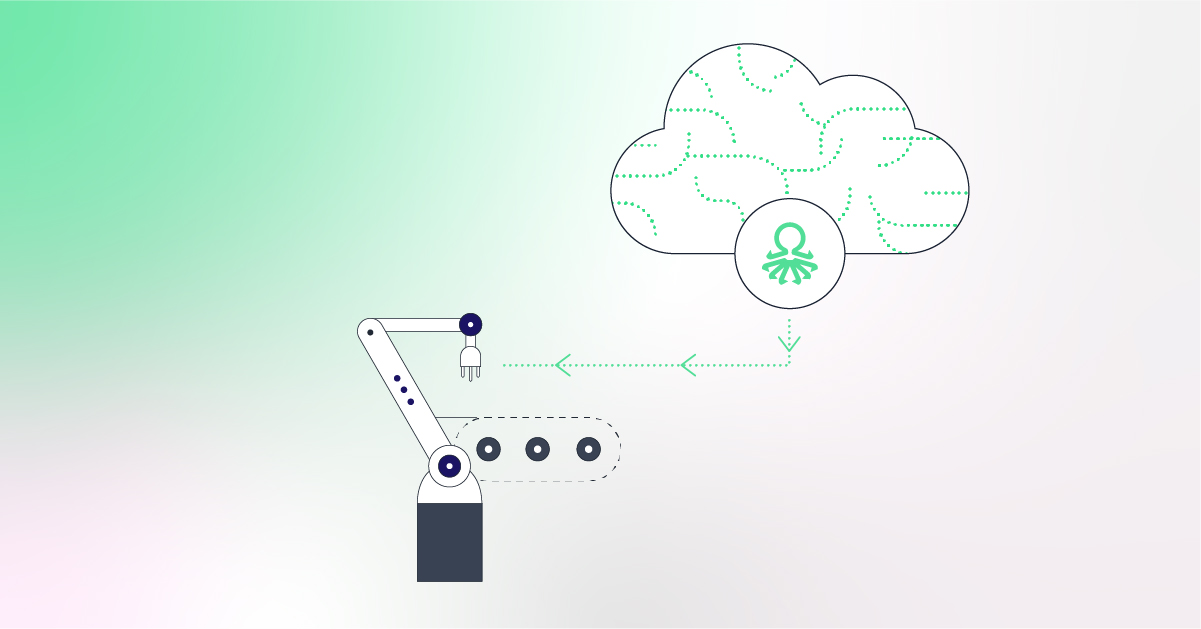

Of course, employees won’t vanish. Many manufacturing companies aim to use AI to enhance how employees carry out tasks, allowing them to operate more efficiently and effectively. Several AI solutions already exist that enable businesses to drive down the cost of production while increasing efficiency, such as Vanti, which removes faulty units from the process.

Artificial intelligence in the process industry aims to save company’s money on materials as well. Allowing a faulty unit to continue in the manufacturing process means processing it further, consuming more materials, and occupying a place on the assembly line that could belong to a functioning unit.

AI Process Optimization Automates Quality Control

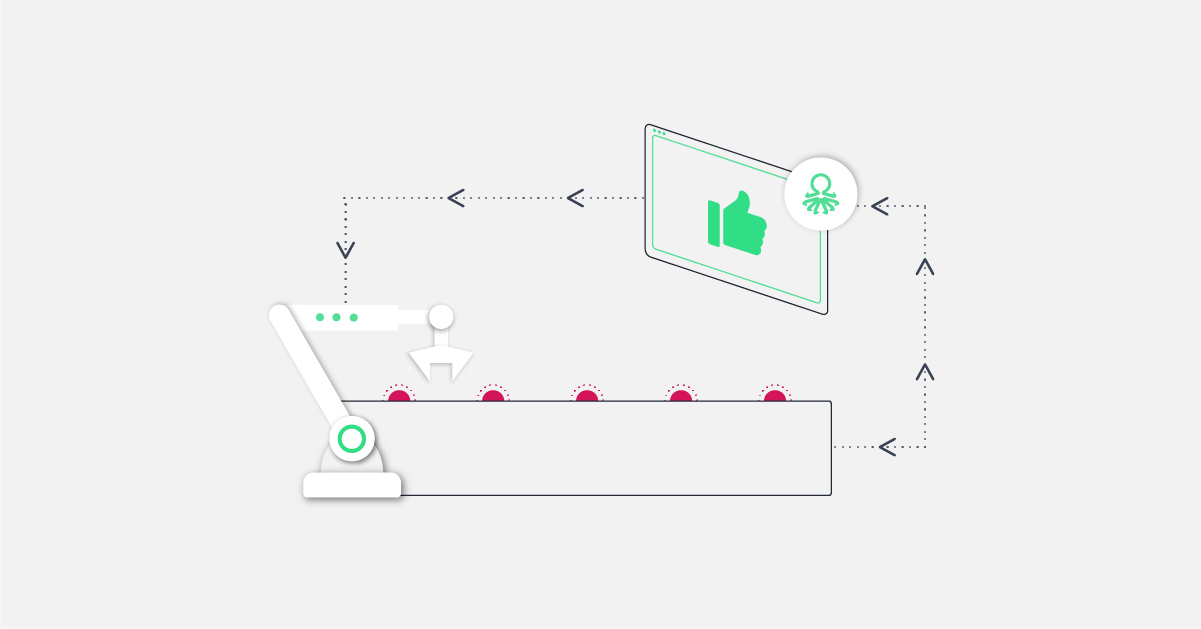

AI in the electronics manufacturing industry can help identify and remove defective units before they waste more time, materials, and energy. Removing them from the process before they consume any more resources can do wonders for increasing throughput and reducing costs.

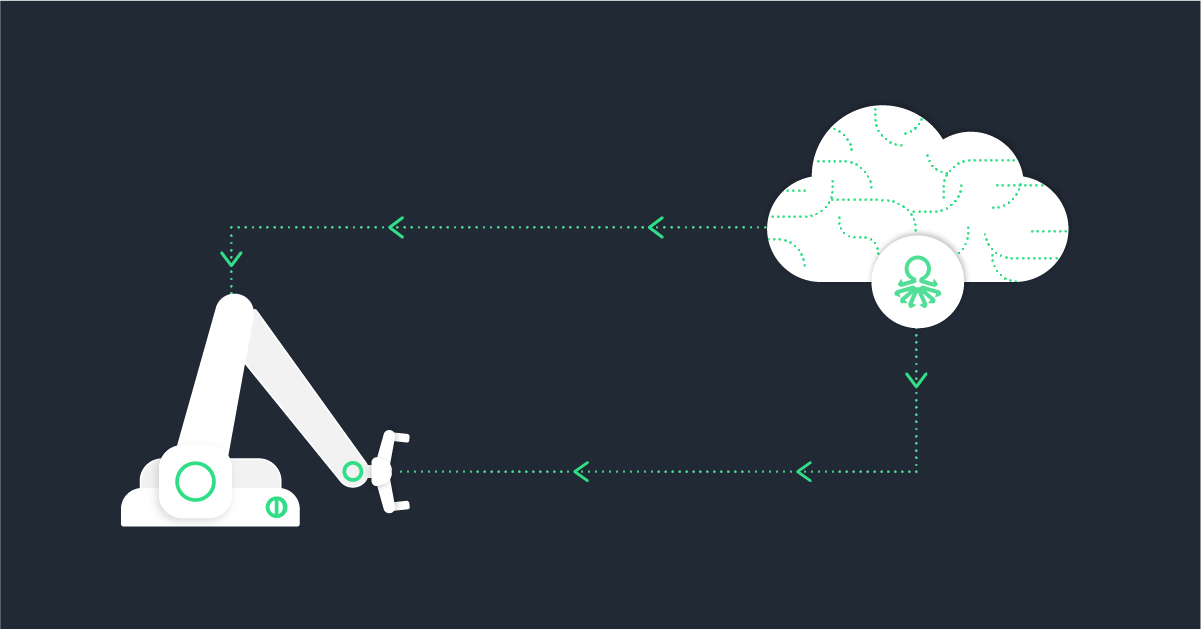

One impact of AI on electronics manufacturing is trusting tedious tasks such as quality control to AI solutions that work with sensors to stop faulty units as soon as possible. Armed with a stream of data coming from multiple sources, AI can target a faulty unit earlier and easier than a human counterpart. For example, detecting faulty units and removing them is a core function of Vanti that functions without human involvement.

Small defects in electronics can easily be overlooked by a human who can become tired, fatigued, or simply not be able to see the defect. AI solutions, on the other hand, are constantly able to use data and sensors to carry out quality control tasks.

Many manufacturers employ skilled engineers to hard-code algorithms that help the system identify faulty and good units. While they can be effective, they cannot adapt and learn, which has the potential to create a high false-positive rate.

Instead of relying on static, hard-coded algorithms to handle the quality control process, artificial intelligence can analyze more information and make data-driven decisions that help spot faulty units quickly. Instead of waiting until the usual quality control processes to discover faulty units, removing them as early as possible saves companies time, money, and energy.

Artificial Intelligence in Manufacturing: A Solution To The Supply Chain Crisis

One of the more urgent issues in electronics manufacturing today is the supply chain crisis. While defect rate will always be an area that can be optimized to increase efficiency, previously some manufacturers might have been able to ignore a slightly higher defect rate since they had sufficient materials to compensate for it. But with today’s unreliable shipments and a level of demand for silicon that far exceeds the supply across several different industries, it’s never been more important to reduce defects.

Ideally, AI solutions for manufacturing could focus on preventing unit faults, errors, and defects before they occur, but is that possible?

The simple answer is yes! A predictive fault prevention AI model will look at your historical data to learn which early-stage station data anomalies and setpoints result in late-stage defects. The model will then analyze the line’s real-time data to alert the user to specific unit defects before they occur. The user can then take proactive steps, such as unit manipulation or machine recalibration, to ensure that the defect never occurs.

Using AI-powered fault prevention can be your secret weapon to overcome the supply chain crisis by reducing defects, maximizing output, and increasing throughput.

What’s Next for Artificial Intelligence in Electronics Manufacturing?

Artificial intelligence is still a young and rapidly evolving technology. And yet, it’s already revolutionizing the manufacturing industry through the rise of Industry 4.0.

As it continues to develop, the electronics manufacturing sector will embrace tools that allow them to fundamentally change the way they produce electronics.

It’s no secret that AI will enable companies to make decisions based on data-driven insights, optimize processes, decrease operational costs, and even aid in providing quality customer service. AI is setting up the electronics manufacturing industry for its next revolution.

Vanti provides leading electronics manufacturers with predictive analytics models that allow them to detect faulty units as early as possible in the manufacturing process. Our models require little training and can be deployed in just hours.

Are you looking to streamline your manufacturing processes and decrease the amount of resources being spent on root cause analysis?