Yield Improvement In Manual Assembly

Real-Time AI-Powered Predictive Quality

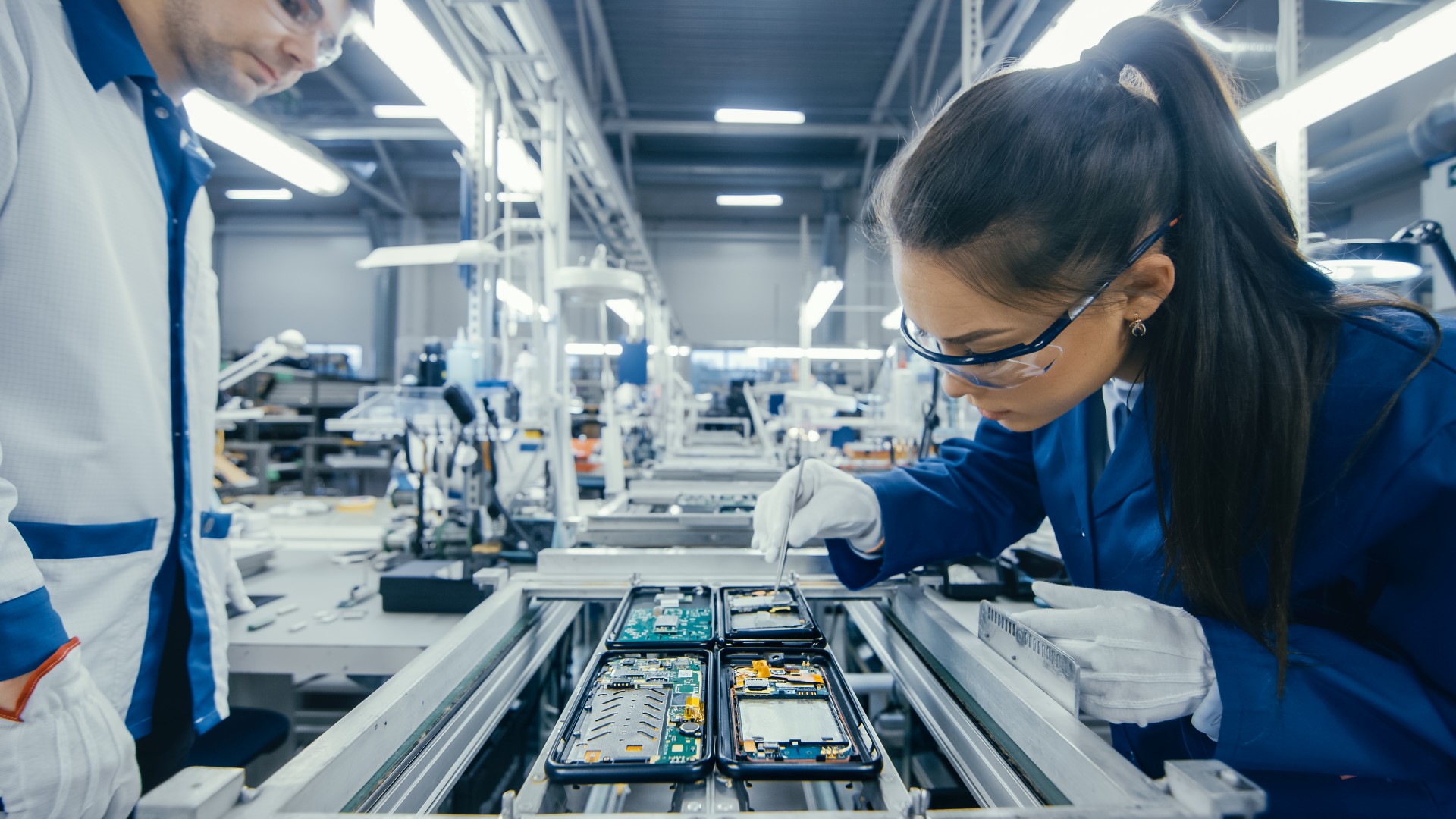

Introduction: A Global Electronics Manufacturer

A leading global electronics manufacturer with 100 plants across 30 different countries producing high volumes of both OEM and white-labeled devices including phones, computers, medical equipment, and robotics, all of which require substantial manual assemblies.

As a leader in their industry, this manufacturer had already completed significant aspects of its digital transformation and was already generating and utilizing the facility data to improve throughput, efficiency, and quality.

-

Challenge:

Increase Yield and Quality of manually assembled units -

Solution:

Video-based & AI-Powered Predictive Quality solution with real-time operator feedback -

Impact:

5X reduction in faulty units and substantial revenue increase

Business Challenge: Increase Yield and Quality By Reducing Errors

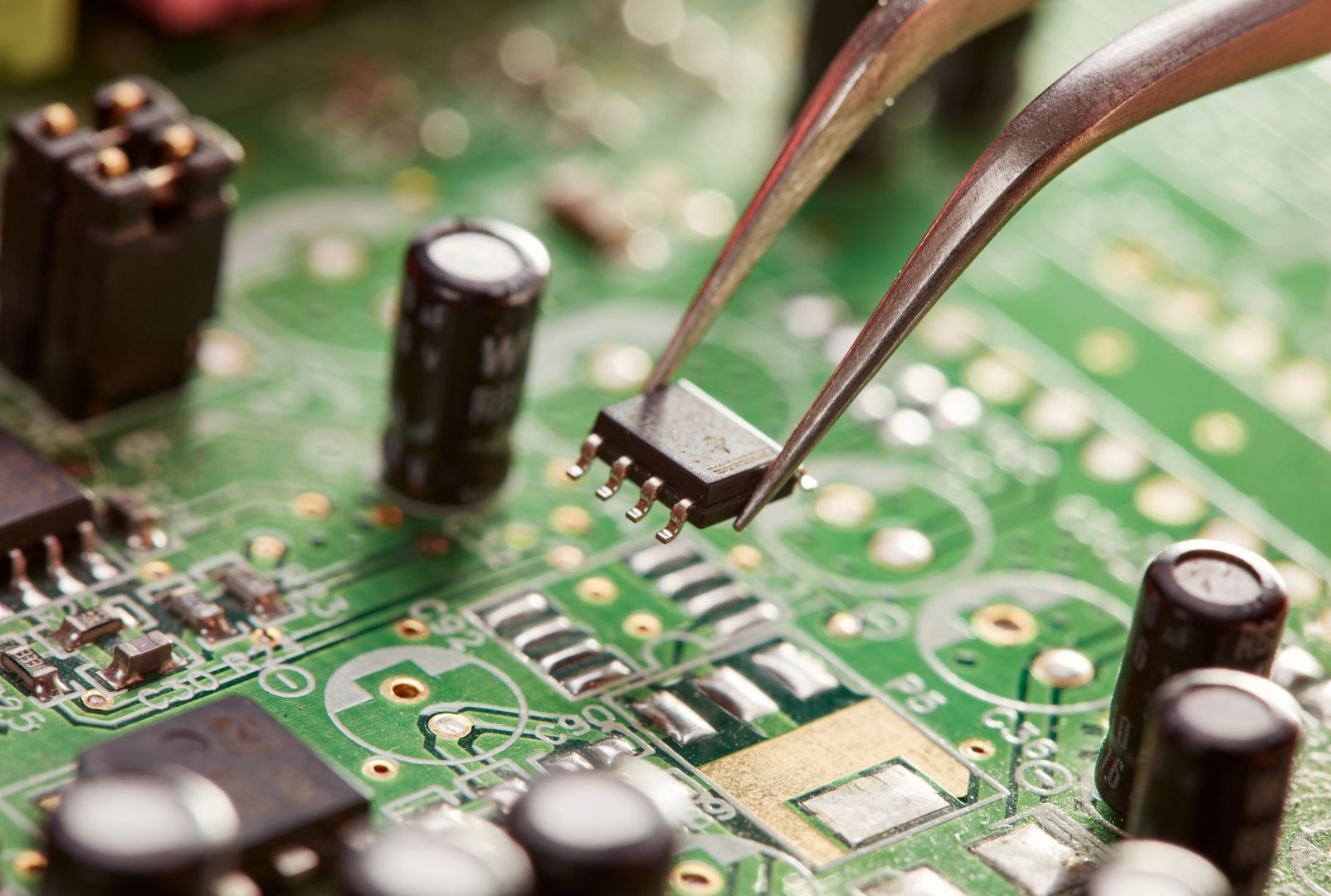

The manufacturer was looking to improve a specific production line producing a computer that had an unsatisfactory defect rate, with more than 5% of units not passing inspection. Due to the fact that problems could only be identified during the end-of-line inspection of fully assembled units, the loss of parts and resources was substantial. As a result, they were looking to predict faulty units at an early stage in the production process, avoiding the efficiency lost for each misassembled unit and resulting in a substantial loss of revenue.

Solution: Video-Based Predictive Quality

The manufacturer’s operations team, supported by Vanti experts, deployed an AI-powered predictive quality solution.

A video camera was installed at a mid-line manual assembly station, providing a live feed of the units being assembled (and not the person). A model was trained using videos of unit assemblies, combined with end ofline inspection results of the same units. The model then produced predictions of the units passing or failing end-of-line inspections.

The entire project took 2 days including the camera installation and data connection to Vanti’s cloud-based solution, with model training and tuning taking only a few hours.

Once deployed, a live video feed of each unit being assembled is uploaded in real-time to the cloud, and a prediction is provided instantaneously to the operator in the form of a green or red traffic light. If green, the units continue to the next station. If red, the operator reassembles the unit until a green light is received.

Results: Vanti’s Impact

Overall, the time-to-value took a total of two weeks, running from inception to deployment. The manufacturer saw significant results immediately, through a dramatic decrease in the number of units that fail their inspection and by improving overall product quality.

Improved Quality

Within two weeks of implementation, the manufacturer’s unit failures dropped by over 90%

Business Impact: Bottom Line

The implemented solution resulted in efficiencies contributing to more than a $200,000 increase in revenue per production line.

When deployed at scale across all lines, Vanti’s AI-powered platform created a total increased revenue of millions of dollars.

Customer Feedback:

“The platform was so easy to understand. The user experience for training and insights was intuitive to understand and the accuracy of the results was perfect.”

Senior Plant Executive