The manufacturing sector is experiencing an unprecedented influx of data from smart factories, IoT sensors, and advanced industrial equipment. While this presents limitless possibilities for optimization, prediction, and efficiency gains, managing and utilizing vast amounts of complex data is a monumental task. Manual, inconsistent data management processes are buckling under rapidly expanding, heterogeneous data from multiple sources. To overcome these hurdles and realize the full potential of their growing data assets, manufacturers need solutions that automate the demanding process of deriving value from unstructured data.

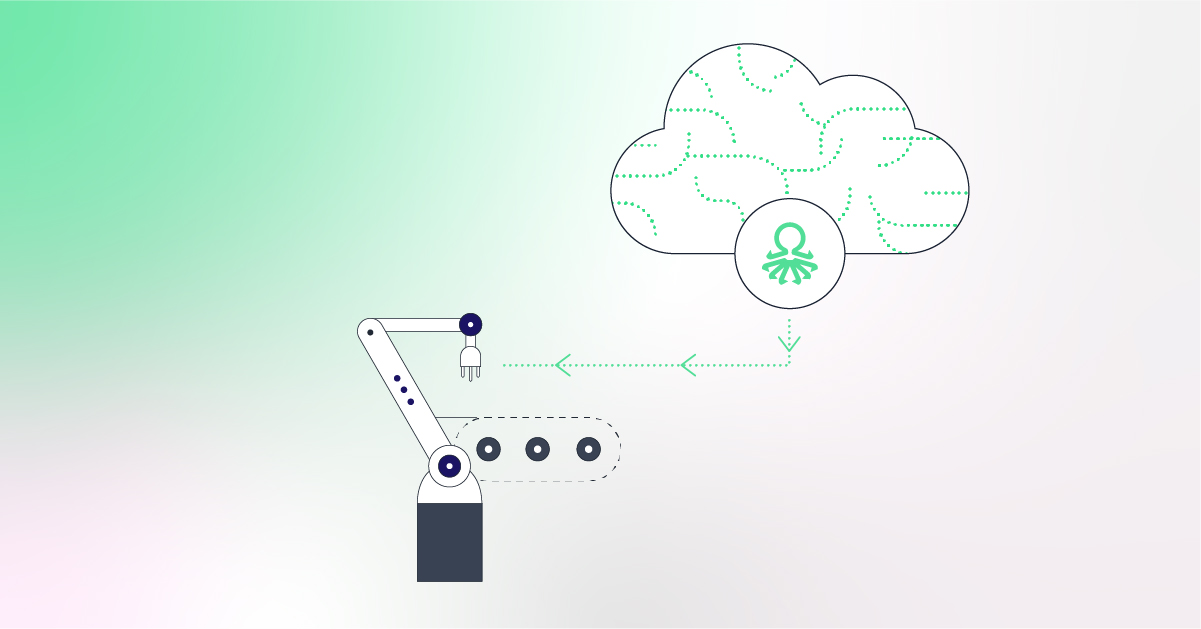

This is where artificial intelligence and machine learning enter the equation. AI tools for manufacturing can readily ingest messy raw data and autonomously curate it into labeled, prepped datasets through data curation for machine learning to deliver the reliable, actionable insights manufacturers require to accelerate digital transformation. However, to build capable data pipelines for next-gen manufacturing, investments in AI solutions tailored to the challenges of heterogeneous industrial data and manufacturing data management are crucial.

In light of the difficulties of scaling industrial data management, this article will examine how AI-enabled automation can help organizations capitalize on their wealth of operational data and apply AI in manufacturing.

The Importance of Data in Manufacturing

The data deluge is largely driven by sensors in production machines, Internet of Things (IoT) devices, and global supply chain networks. This encompasses vibration, power usage, temperature, and pressure readings across industrial equipment. Additionally, in expansive industrial IoT networks, devices continuously exchange vital data on inventory levels, logistics, asset locations, and more.

Harnessing this new trove of manufacturing data presents tremendous upside for businesses. To generate insights that optimize all facets of production, manufacturers need access to high-quality, contextualized data enabled by leading-edge technologies like artificial intelligence, machine learning, and predictive analytics. The end goal is consolidating this disparate data without disrupting existing systems to gain unparalleled visibility into every link of the value chain.

However, the exponential increase in production data poses significant challenges in management, integration, and utilization. Key pain points in industrial data management must be addressed before the full potential of this data can be realized. Here, we examine some of the most critical obstacles manufacturers must navigate to maximize their expanding data stores for increased output and profitability. Overcoming these data roadblocks is imperative for manufacturers to transform raw data into operational intelligence.

Challenges with Manufacturing Data Management

Data management in manufacturing is notoriously tricky to manage due to its sheer volume, variety, and velocity. Data flows in from ERPs, MES, sensors, legacy record systems, spreadsheets, and more. Much of these records tend to be unreliable due to background noise, inaccuracies, omissions, and outliers. The lack of standardized formats, taxonomies, and definitions across systems and sources makes it extremely difficult to integrate salient data points from multiple disparate systems into unified, consistent datasets and meaningful perspectives. Data is typically trapped in siloed repositories, preventing access or integration. Unclear data governance obscures proper conveyance of the right information to the right people at the right time. Ownership hierarchies and semantic connections can be murky.

Manufacturing data preparation and curation requires extensive manual effort and expertise to detect data issues, cleanse, normalize, and enrich datasets prior to analysis. The constantly shifting nature of the production floor makes it challenging to maintain accurate, consistent data. As shop floor technologies evolve, so do the available data sources.

These widespread data management challenges make consolidating, contextualizing, and effectively utilizing manufacturing data notoriously difficult. The vision of data-driven smart manufacturing will remain elusive unless these foundational issues are addressed. Taming the complex manufacturing data landscape is imperative for driving analytics and intelligence on the plant floor.

The Criticality of Data Curation

The difficulties of managing massive amounts of unstructured manufacturing data underscore the importance of curating and preparing it for analysis. Indeed, proper curation of raw manufacturing data is crucial before it can be leveraged for analytics. This involves activities like cleaning, standardizing, enriching, and applying semantics. Insights can only be gleaned from the right context. Components of this data curation process can be automated with the application of artificial intelligence in manufacturing. Both natural language processing (NLP) and machine learning (ML) can be used to correct inaccurate data. AI helps factories turn their growing data repositories into a useful strategic asset for improved decision-making and operations.

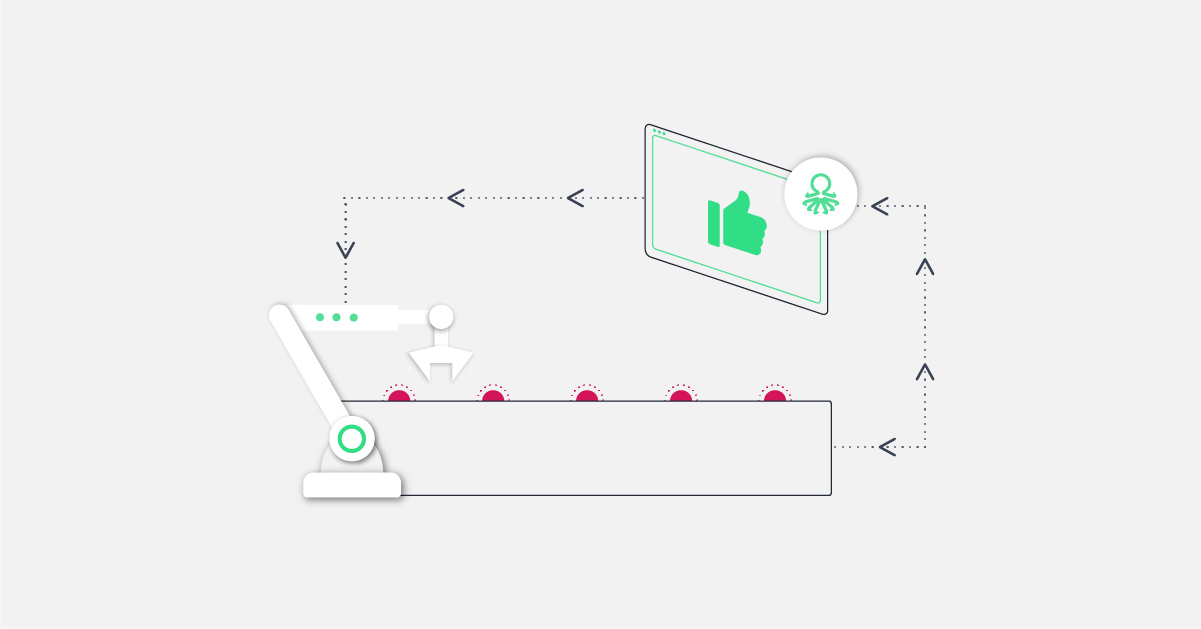

Curated data improves the quality of analytics by eliminating irrelevant information and correcting errors. Access to high-quality, labeled training data with relevant features is critical for machine learning. Up to 80% of time on machine learning and AI projects is spent on data preparation. It is an essential prerequisite for more advanced analytics.

Moreover, curation is an ongoing process. Maintaining governance and improvements is vital as new data issues and sources emerge. Continuously monitoring data quality and consistency is imperative. Appointing data stewards with production knowledge ensures proper context and governance are upheld.

Poor data quality results in manufacturers losing money from production downtime, supply chain interruptions, inaccurate forecasts, and more. However, well-curated data enables optimization at every stage of the value chain from product development to marketing. Industrial data presents unique challenges, requiring a data curation strategy and solution tailored to the task. Specialized software can automate curation to remove the drudgery.

Vanti’s AI-Powered Data Management for Manufacturing

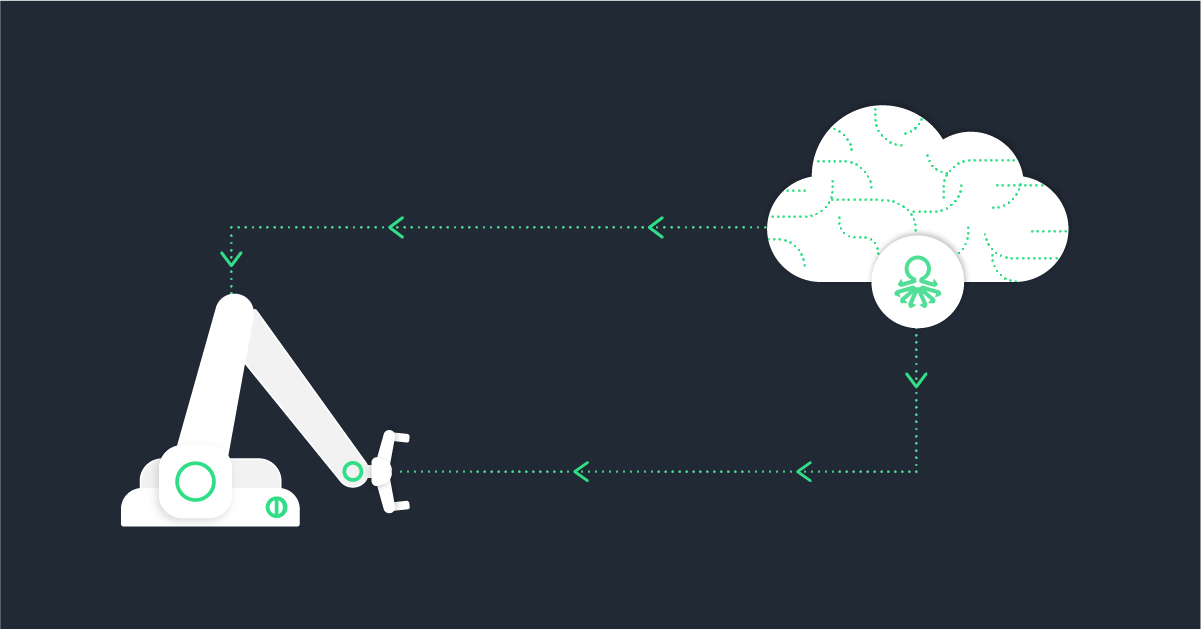

Vanti is an intelligent, manufacturing-specific data management solution. Vanti utilizes AI and domain expertise to streamline data preparation and consolidate siloed manufacturing data into a unified model ready for analytics.

Key capabilities of the Vanti platform include:

- Data Ingestion & Processing: Vanti provides out-of-the-box connectivity to the wide range of ERPs, sensors, MES, and databases prevalent in manufacturing. It makes it easy for users to locate and bring in the data they need.

- AI-enabled Curation: Vanti leverages AI algorithms and domain knowledge to curate the industrial data you supply by cleansing, standardizing, and enriching it. This saves significant manual time and effort compared to standard data tools.

- Manufacturing Data Semantic Engine: Performs semantic analysis on unstructured text data to uncover relationships across disparate data sets. It consolidates the information into a streamlined dataset optimized for analysis. The engine learns the specific data relationships of your organization to streamline operations.

Vanti’s ability to handle this complex domain by combining automated data wrangling with an understanding of the context and meaning of manufacturing data is a major breakthrough. It significantly enhances the efficiency and quality of data curation compared to standard data platforms through its manufacturing semantic layer.

Vanti enables manufacturers to unify their fragmented data landscapes into a unified framework from which data can be accessed and analyzed with minimal friction. Rapid data preparation allows near real-time analytics applications. Vanti’s simplicity of data consolidation, embedded intelligence, and speedy analytics prep empowers users to maximize value from AI and manufacturing expertise.

The Benefits of Vanti for Manufacturers

Vanti provides manufacturers with a consolidated data platform, turning disparate data sets into one cohesive model. Our solution rapidly curates manufacturing data by leveraging AI algorithms and extensive domain knowledge. Automating mundane data preparation tasks like cleansing and normalization accelerates time to insight and improves data quality.

Vanti’s flexible semantic layer captures intricate relationships within data, enabling non-expert analysis. This allows personnel across roles to easily access tailored, domain-specific data relevant to their needs. Vanti seamlessly incorporates fresh sources as they emerge on the factory floor to power AI/ML initiatives.

By rapidly preparing data for analytics, Vanti enables manufacturers to fully leverage models for process optimization and more. Ultimately, the comprehensive, high-quality data consolidated by Vanti improves enterprise-wide decision making. Enriched insights from Vanti-powered analytics drive measurable operational improvements on the manufacturing floor.

Key benefits of Vanti’s unified platform include increased efficiency, lower errors, and consolidating messy IT infrastructure into a single solution. Both business and IT users gain from a singular, analytics-ready data resource versus fragmented, raw data stores. By combining automation, expertise, and AI for data curation, Vanti delivers significant value across data quality, speed, flexibility, decision making, and costs.

Conclusion

As manufacturing becomes more data-driven, efficiently managing increasingly complex data environments is imperative. Data volume, variety, silos, governance, and the manual toil required to curate and prepare data for analytics pose major hurdles.

Vanti is one example of a platform leveraging artificial intelligence to transform manufacturing data management. By automating curation and providing a semantic layer tailored for industrial data, Vanti enables users to better organize, interpret, and utilize their data. This paves the way for improved decision-making across the value chain and helps manufacturers overcome critical data challenges.

As the need for industrial analytics continues to rise, solutions like Vanti that apply AI for enhanced data management will become even more crucial. Contact us today for a demo of Vanti to see how it can aid your transition to data-driven manufacturing.