LLM Applications for Production – An Overview

If you haven’t heard already, Large language models (LLMs) like GPT-4, Claude2 or LLaMa2 are poised to transform manufacturing in major ways. By leveraging the power of AI and machine learning, LLM applications can optimize production, improve quality control, enable predictive maintenance, and much more. In this post, we’ll explore the key ways LLMs are revolutionizing industrial manufacturing across a wide range of use cases.

But before that, let’s go back to the basics. LLMs represent a breakthrough in natural language processing. They are trained on massive datasets of text data, allowing them to generate human-like text and insights. This ability to understand and generate text makes them incredibly versatile. When focused on a particular domain like manufacturing, LLMs can become powerful AI assistants, capable of understanding complex manufacturing processes and providing valuable insights.

Today, leading technology companies are leveraging LLMs to build tailored solutions for manufacturers. This includes predictive maintenance apps, computer vision quality inspection tools, production planning assistants, and more. And the adoption of LLMs is only accelerating as their capabilities improve and deployment costs decrease. As more manufacturers realize the potential of these models, we can expect to see a significant surge in their use across the manufacturing industry.

One such company at the forefront of this revolution is Vanti Analytics. Vanti’s generative AI solution merges all manufacturing data into an insightful knowledge hub that understands and responds to natural language. This AI-powered data wizard provides insights in minutes, not weeks, and automates data engineering tasks, allowing manufacturers to focus more on drawing insights and less on cleaning and managing data.

Large Language Models in Manufacturing – Driving Predictive Insights

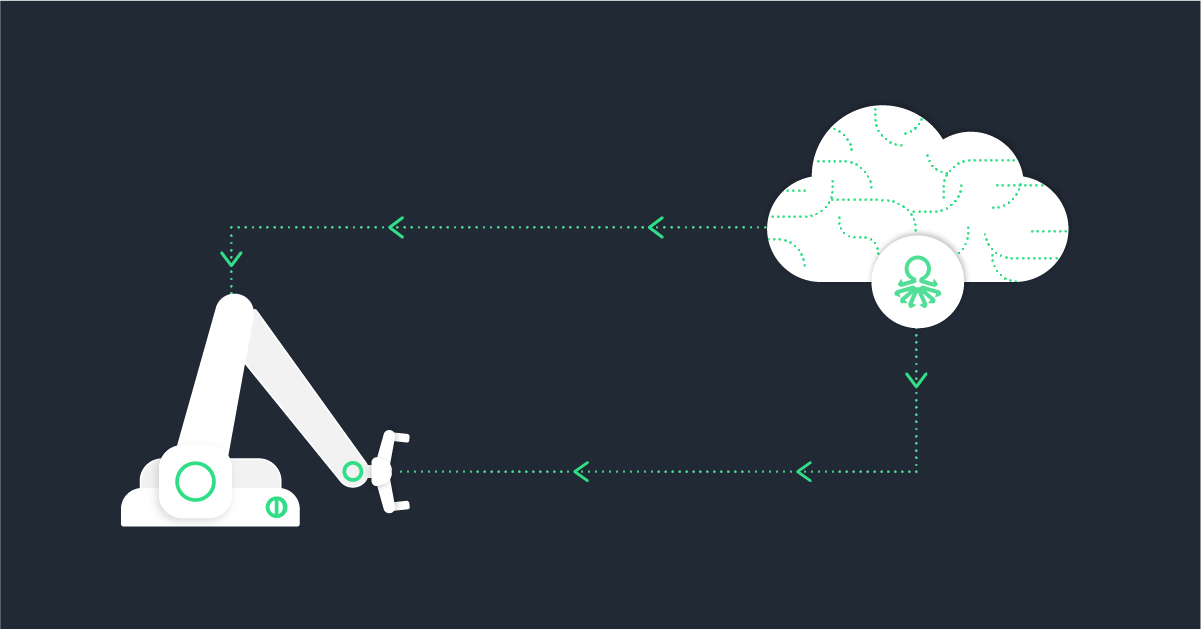

As mentioned earlier, one of the biggest values of LLMs in manufacturing is their ability to analyze massive amounts of data and identify patterns. This allows manufacturers to gain predictive insights that can greatly streamline their operations.

For example, LLMs can forecast equipment failures before they happen based on past maintenance logs, error logs, sensor data and more. By processing thousands of data points across machines, the LLM can identify signals that predict imminent failures. Manufacturers can then proactively schedule maintenance at optimal times. This ability to predict and prevent equipment failures can significantly reduce unplanned downtime, leading to increased productivity and reduced costs.

Vanti’s solution excels in this area, providing early fault prediction and defect detection. It integrates manufacturing data from multiple sources, utilizing all of them to get an understanding of the actual process. This allows for a comprehensive understanding of plant behavior and enables smarter decision-making.

In addition, LLMs can also predict future demand with high accuracy based on historical trends, economic indicators, and emerging customer preferences. By processing both structured and unstructured data, the LLM can uncover demand drivers difficult for humans to manually piece together. Manufacturers can align production schedules and inventory levels to meet demand. This reduces overproduction and excess inventory costs, leading to more efficient operations and improved profitability.

In essence, LLMs allow manufacturers to spot issues and opportunities earlier. This enables proactive optimization rather than reactive firefighting. The ability to predict outcomes before they occur is extremely valuable. Vanti’s generative AI solution, with its ability to provide insights in minutes is a perfect example of how this technology can be leveraged for predictive insights.

LLM in Industrial Manufacturing – Automating Quality Control

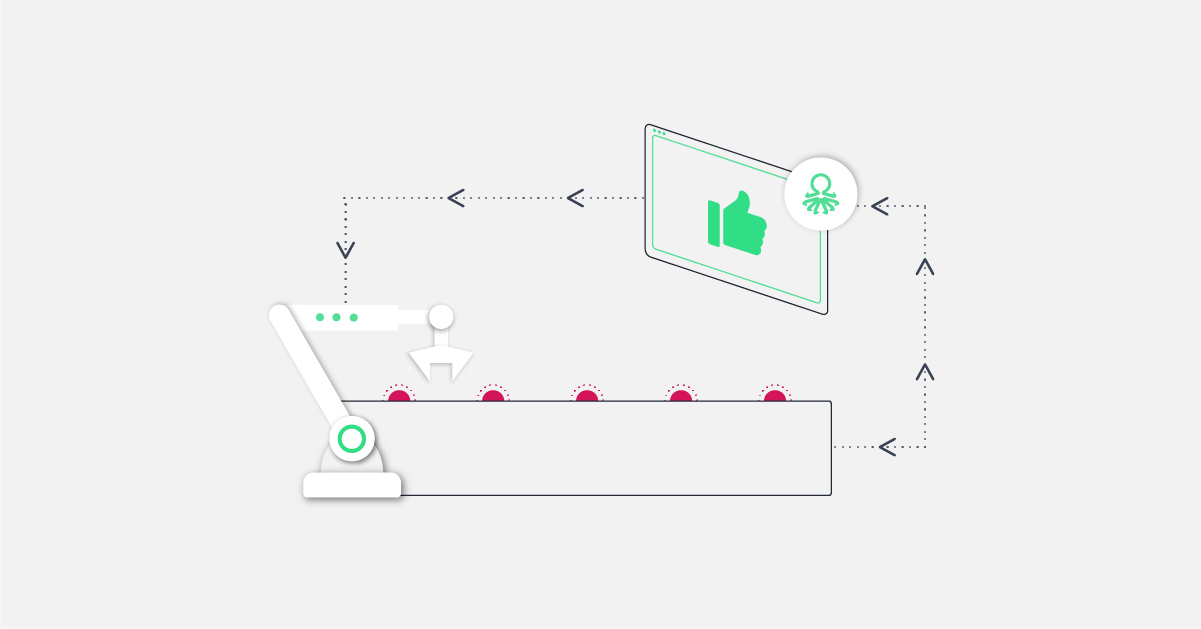

Maintaining quality control is crucial but time-consuming in manufacturing. LLMs can automate parts inspections to catch defects rapidly.

Computer vision LLMs can scan manufactured items on the production line and detect any deviations from design specs. The LLM is trained on thousands of images of passing and failing parts to learn subtle visual defects. For example, AI inspection can catch microscopic cracks or inadequacies human inspectors would likely miss.

Vanti’s next-generation visual defect detection is a prime example of this application. By integrating AI into the quality control process, manufacturers can significantly improve their defect detection rates and reduce the time and resources spent on manual inspections.

LLMs can also analyze sensor data from machinery to detect any abnormalities indicating quality issues. The LLM identifies patterns leading to defects across sensors for temperature, vibration, pressure and more. Anomalies in readings can flag potential defects.

This automated quality inspection improves detection rates and reduces manual oversight needed. Products with fewer uncaught defects lead to lower warranty costs and higher customer satisfaction. Freeing up human inspectors enables them to focus on higher-level process improvements.

Building LLM Applications for Production – Enhancing Processes

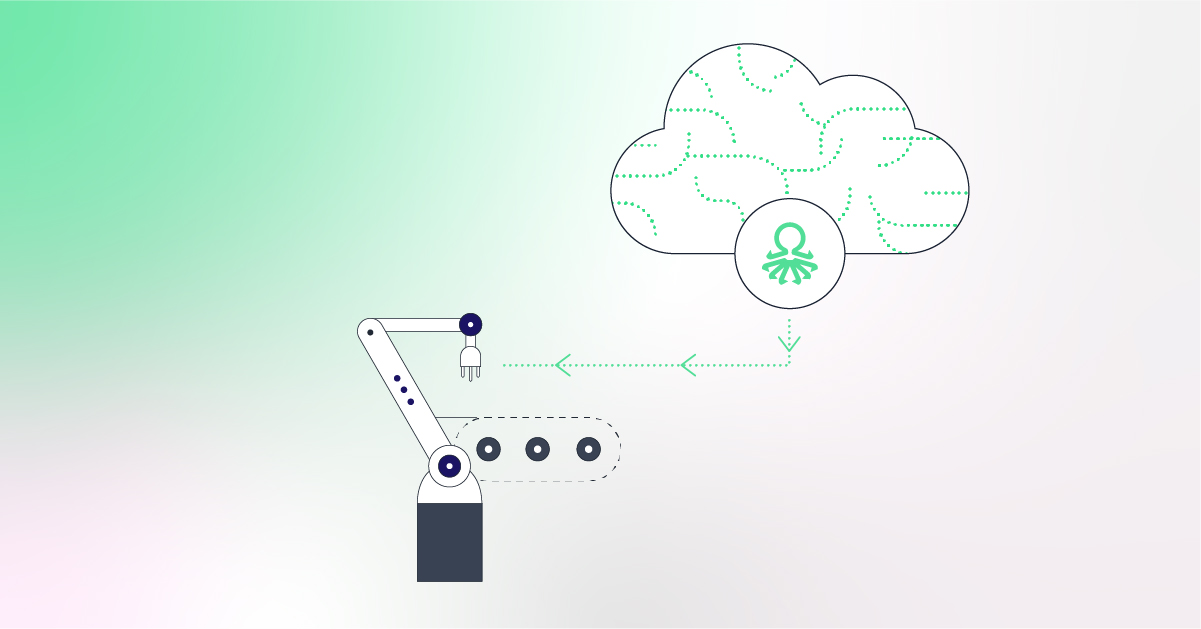

Continuing our discussion, LLM applications could complement human operators in manufacturing. Combining AI data analysis with human expertise and oversight may enhance workflows. The goal is an inclusive approach where people and AI collaborate to increase productivity and quality.

As one example, LLMs can dynamically schedule machine processes to minimize changeover time. By analyzing all present tasks and requirements, the LLM can determine the optimal batching, sequencing and assignments to reduce downtime. The model is trained on past production data to learn ideal scheduling heuristics.

Vanti’s generative AI solution shines in this area as well, offering industrial process optimization and process tuning time optimization. By integrating AI into the production process, manufacturers can significantly improve their efficiency and reduce downtime.

LLMs can also fine-tune equipment operating parameters for peak performance. By processing data on product tolerances and machine capabilities, the LLM can define the ideal settings to balance speed and quality. Real-time adjustments prevent output deviations.

During production, the LLM can monitor all sensors and flows to rapidly detect and troubleshoot any process deviations. Quick automated adjustments prevent bottlenecks or defects. Essentially, the LLM identifies developing issues before they escalate based on past patterns.

Overall, LLM-powered manufacturing leads to faster production at higher and more consistent quality. LLM applications enhance human capabilities for optimal results. With solutions like Vanti’s generative AI, manufacturers can leverage the power of LLMs to gain a distinct competitive advantage.

Harnessing the Power of LLMs – A Strategic Approach to Future Manufacturing

As we navigate the future of manufacturing, it’s clear that large language models (LLMs) like GPT-4 and AI solutions like Vanti’s generative AI are not just tools but transformative forces that are redefining the industry. They are revolutionizing how we approach production, quality control, predictive maintenance, and process optimization.

The integration of AI into manufacturing processes is no longer a luxury but a necessity for companies aiming to stay competitive in the digital age. The ability of LLMs to analyze vast amounts of data, identify patterns, and generate human-like text and insights is driving efficiency, reducing costs, and improving product quality.

Key opportunities lie in predictive maintenance, quality automation, production optimization, resilient supply chains, and custom designs. While LLMs require an upfront investment, the long-term rewards are invaluable. When developing an LLM application, it’s critical to train the model on domain-specific data to build necessary capabilities. Clean, comprehensive data leads to more accurate insights, and ongoing training refines the model as new data is acquired.

Moreover, the role of AI solutions like Vanti’s generative AI cannot be overstated. By merging all manufacturing data into an insightful knowledge hub that understands and responds to natural language, Vanti is helping manufacturers draw insights in minutes, not weeks, and automate data engineering tasks. This is freeing up valuable time and resources, allowing manufacturers to focus more on strategic decision-making and less on data management.

LLMs and the Future of Manufacturing – Embracing a New Vision

By integrating LLMs, manufacturers gain a significant competitive edge. The ability to swiftly respond to customer needs, improve quality standards, and maintain operational efficiency amidst uncertainty is a game-changing advantage. The transformative capability of LLMs, as illustrated by leading firms such as Vanti, is a reality that manufacturers should embrace.

To sum up, adopting LLMs and AI solutions signifies an innovative thought process, a fresh problem-solving approach, and a groundbreaking vision for the future of manufacturing. This transition keeps you ahead of the evolving industrial landscape, ensuring your competitiveness in a rapidly digitalizing world. As we continue our journey into the depths of these technologies, we envision a future where manufacturing is smarter, more efficient, and adept at meeting dynamic market demands.

To explore the use cases of LLMs in manufacturing and to understand how your organization can benefit from this technology, we invite you to engage in a conversation with our experts at Vanti. Start your journey towards the future of manufacturing today!