AI-powered Industrial

Predictive Quality

Predict product quality issues earlier to increase Quality, Efficiency and First-Pass Yield

Predict Defects Before They Happen

Improve First Pass Yield

Avoid Sub-quality Batches

Deploy in Days, Not Months

Eliminate product defects and production slowdowns due to halts. Vanti’s AI-powered Predictive Quality solution uses machine learning and data analytics to help identify product quality issues earlier on the factory lines—reducing defects, costs and maximizing uptime. Vanti analyzes production data to identify patterns, anomalies, and potential issues, providing actionable insights for engineers and plant floor managers

Predict Quality Issues Earlier

Ensure consistent, high-quality production with real-time, AI-based alerts in the flow—as soon as there is a problem. Identify root causes quickly and get predictions with comprehensive insights on what can go wrong. Leverage analytics dashboards for root cause analysis, or utilize real-time operator alerts for proactive corrections.

Accelerate Time to Value

Realize value quickly by empowering your domain experts with a no-code solution that doesn’t require data science knowledge. Accelerate your digital transformation with quick deployment options and utilizing existing data from sensors, IoT, SCADA, MES, ERP, and any open APIs.

Achieve Tangible Business Outcomes

Get real business results to stay competitive in the market. Reduce production halts, unnecessary scrap wastage, and line rework effort to improve first-pass yield and ensure quality consistency across batches, so that every batch is a “golden batch”.

Industry Use Cases

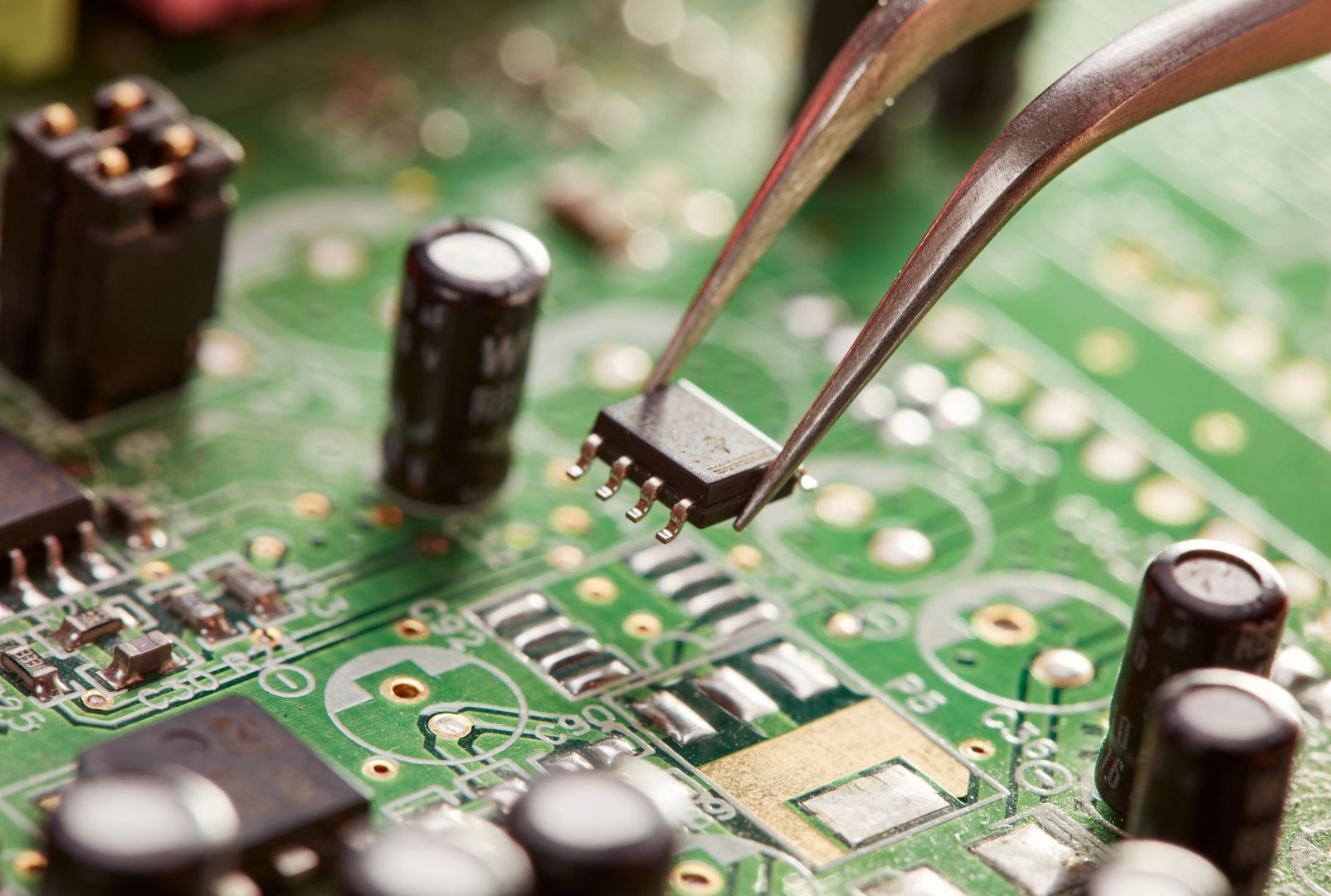

Electronics

Medical Devices