First pass yield is a key performance indicator (KPI) that measures the successful manufacturing of a given product. It’s a great KPI for understanding how successfully a given manufacturing process is at creating functional products.

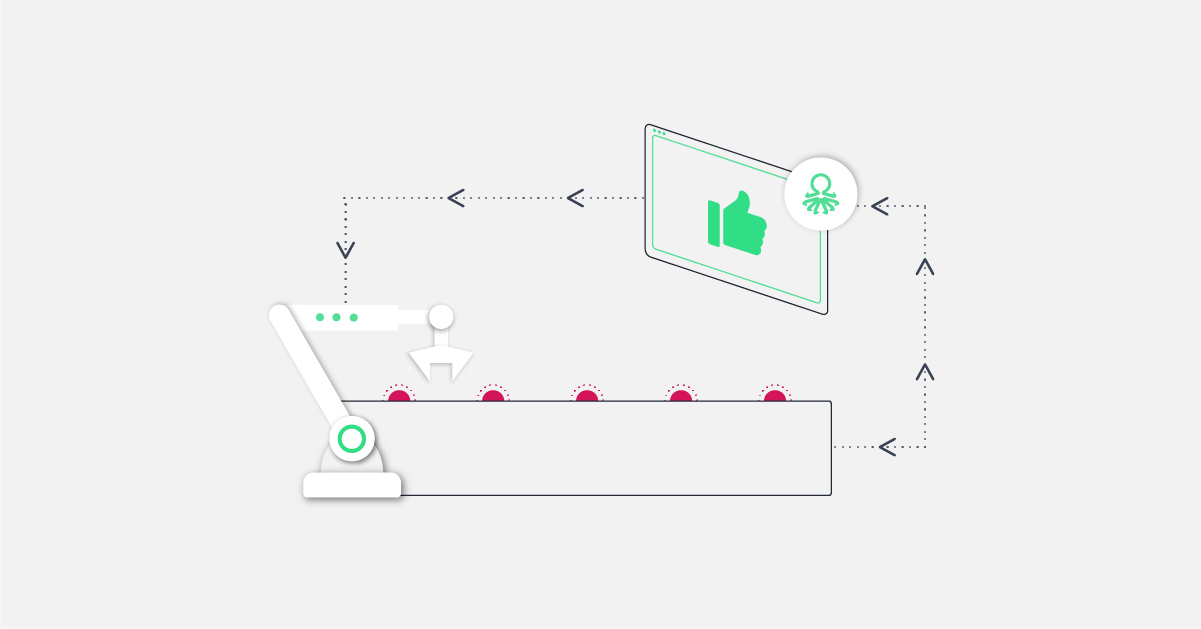

Knowing that, it shouldn’t surprise you that quality control in electronics manufacturing is one of the best ways to improve first pass yield. Companies in all industries rely on this process to identify and remove faulty units from the manufacturing process to ensure more throughput is focused on functional units.

But mastering quality control isn’t easy.

Almost every electronics manufacturer is looking for new ways to reduce inefficiency and waste. And despite initiatives being regularly launched, without an effective way to measure first pass yield, they will struggle to identify the success or failure of these new processes.

So, what can you do to improve your approach to first pass yield? Keep reading to see our first pass yield analysis, and how you can better use this important metric.

What Is First Pass Yield?

If your organization is not currently measuring first pass yield, you may not know the first pass yield formula. The formula itself is quite straightforward:

- First yield pass equals completed units that do not require rework / total number of units that began the process

Let’s illustrate the first pass yield calculation with a straightforward example. If there are 100 units that begin the process and 98 are completed to specification and pass every quality test, and two units require rework, then your first pass yield would be:

- First pass yield = (98-2) / 100 = 0.96 = 96%

Now that you understand how to calculate this important KPI, it’s worth understanding its limitations.

Problems With First Pass Yield

First pass yield is not a perfect metric that every company should push to 100% at all costs. At first glance, many manufacturing experts might recognize that it does not take into account the capacity of a specific process, production schedule, or downtime.

Every industry will have a different standard for an acceptable first pass yield. However, it’s difficult for companies to know what a successful first pass yield looks like since not every company publicizes this KPI. Performance varies by industry, so executives should understand what they should be striving to reach.

What Is Yield in Production?

There are several different types of yield in electronics production. All of them play a role in understanding the efficiency of your manufacturing process.

- Output yield: This yield measures failures that result in having to completely scrap a unit and is often close to 100% for most companies.

- Rework yield: If a unit is deemed faulty, it may need reworking instead of being scrapped. This yield is often close to between 90-100%.

- First pass yield: Units must pass or fail specific tests to calculate this KPI. The percentage can vary by industry.

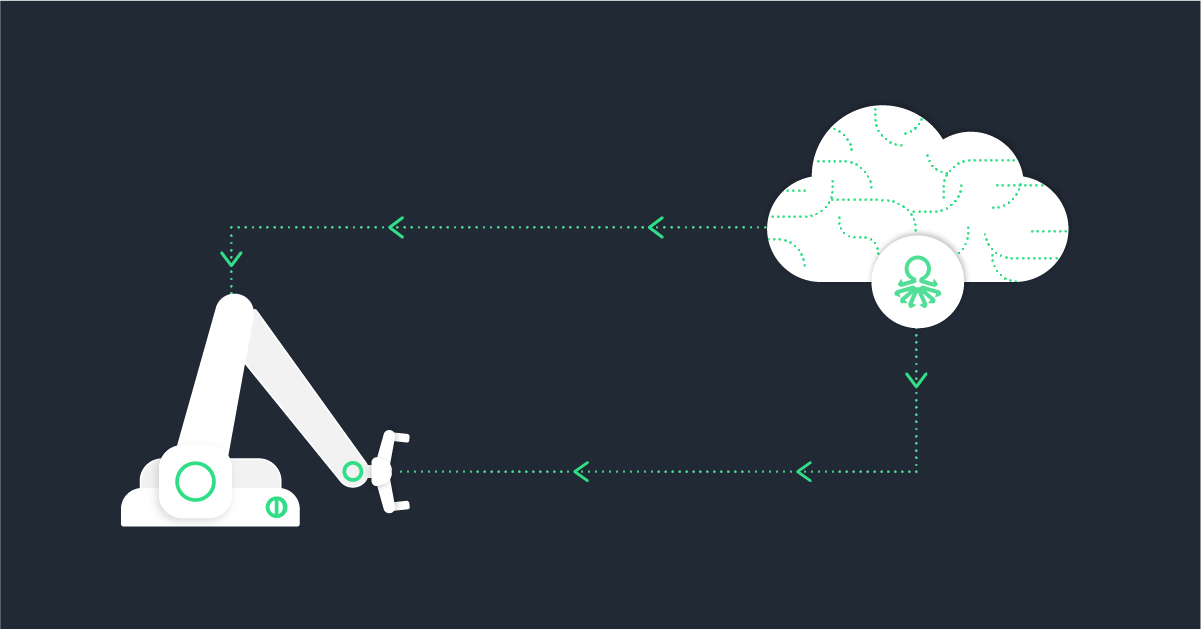

As you continue to improve your operation, you should understand that these important metrics are based on testing units. Having an AI-powered system that uses sensors and a stream of relevant data will help you determine faulty units early in the process can help you increase first time yield.

First Pass Yield Is Not About Improving Quality

First pass yield might seem like a way to enhance the quality of your product, but that’s not entirely true. Instead, it ensures that the product that leaves the facility is the right product.

You’ve already designed a product that you believe your ideal customers will buy. Producing this product correctly means that your customers will buy it. Improving first pass yield dictates that you’ll have more units available for your customers, while ensuring these units will be the desired quality.

Simply put: there is a certain point of diminishing returns when investing in improving first pass yield. You might discover that taking your first pass yield from 85% to 95% reduces costs and increases efficiency, which boosts profit. However, further improving from 95% to 100% may require significant investment that will only slightly improve your yield.

Improve Your First Pass Yield With Predictive Analytics

One of the best ways to improve first pass yield is to identify and remove faulty units early in the manufacturing process.

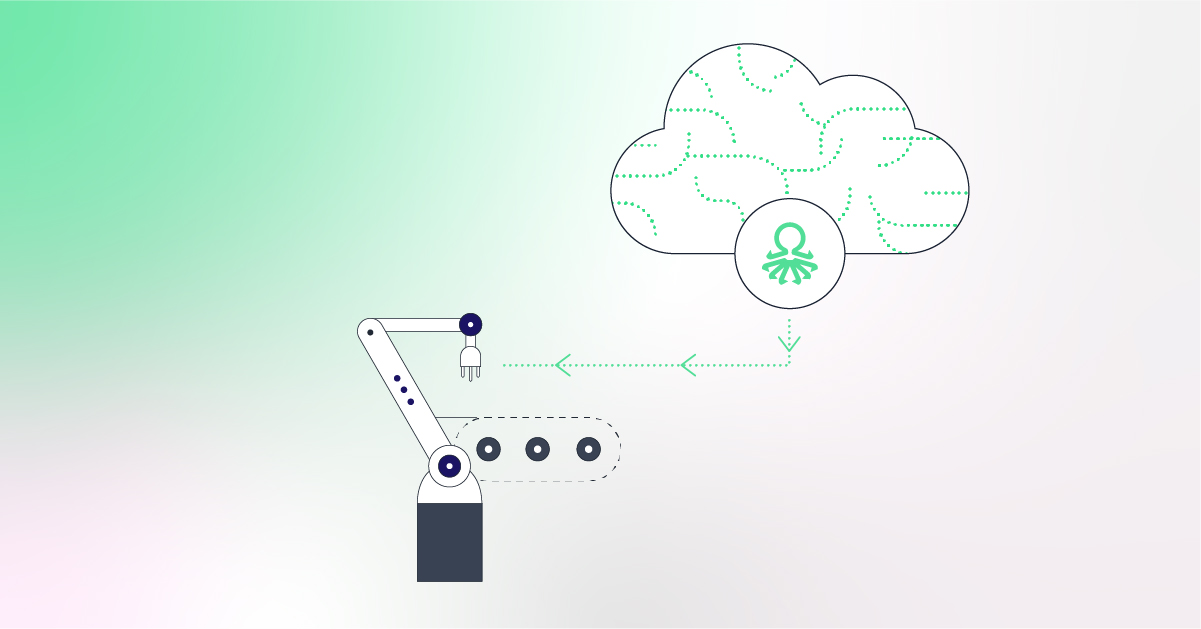

Vanti-Analytics uses powerful artificial intelligence and machine learning models to help manufacturers unlock hidden value in their manufacturing processes.

Are you looking to implement a best-in-class solution for determining first pass yield? Book a discovery call today and see how easy improving first pass yield is with Vanti-Analytics.