Introduction

In today’s competitive world, manufacturing performance is top of mind for industrial organizations to stay profitable and relevant. To achieve optimal manufacturing performance, organizations must use resources effectively, reduce waste and inefficiencies, and optimize the manufacturing process.

As such, manufacturing performance can be measured through various metrics, such as productivity, quality, lead time, flexibility, and cost. Once the measurement is done, plant managers should identify areas of improvement with KPIs and implement changes to optimize the manufacturing process.

AI-powered no-code platforms help subject matter experts to improve manufacturing performance without the need to learn data science. They provide tools for visual defect detection, early quality forecast, and process optimization that help keep equipment speed at optimum levels.

In this blog, we will discuss how solutions like this can be used to improve manufacturing performance and provide examples of its implementation in the Consumer-Packaged Goods (CPG), Electronics, Automotive, and Food and Beverage industries.

Let’s begin.

Understanding Manufacturing Performance

Manufacturing performance can be broadly defined as the effectiveness and efficiency of a manufacturing operation. But if we dig deeper, manufacturing performance refers to the manufacturing process’s ability to produce products that meet customer demands while minimizing production costs and lead times.

Another way to interpret manufacturing performance is as a key component that goes into the calculation of Overall Equipment Effectiveness (OEE), which is calculated as multiplying Availability, Performance, and Quality. In this formula, manufacturing performance is calculated by comparing the equipment’s actual operating speed to its maximum speed, i.e., (Actual Equipment Speed / Maximum Equipment Speed) x 100.

However, if we take the broader definition of manufacturing performance, there are several key performance indicators (KPIs) in the industry that are commonly used to measure it. We will cover these next.

Key Performance Metrics for Manufacturing

Manufacturing performance metrics differ depending on the industry and product being manufactured. However, some metrics are universally applicable across industries and can provide valuable insights into the manufacturing process’s effectiveness and efficiency. Let’s investigate some important performance metrics examples:

Throughput:

Throughput is a measurement of how quickly a production system produces usable goods over a predetermined period in the manufacturing industry. This KPI is commonly estimated as the number of units produced per unit of time, so it is desirable for this KPI to be high for superior performance.

Yield:

Yield measures the ability of the manufacturing process to produce high-quality products in the manufacturing line or plant. In other words, yield is calculated as the proportion of usable products produced to total products produced. A low yield can indicate manufacturing process inefficiencies that must be addressed to reduce waste and improve profitability.

Efficiency:

The ability of the manufacturing process to use resources effectively, such as labor, materials, and energy, is measured as efficiency. It is an important metric for identifying waste reduction and cost-cutting opportunities. Needless to say, efficiency should be high.

Lead time:

The duration required to complete a manufacturing process from start to finish is referred to as lead time. Lower the lead time, higher the performance. Thus, manufacturers can improve throughput and customer satisfaction by reducing lead time.

Quality:

Quality is an important factor in manufacturing because it directly affects customer satisfaction and retention. Quality can be measured using a variety of criteria, such as the number of defects or errors encountered during production, customer satisfaction rates, or compliance with industry standards. Naturally, manufacturers want higher quality.

Cost:

Cost is an important metric in manufacturing because it directly affects profitability. It includes labor, materials, and overhead costs and can be used to identify cost-cutting and waste-reduction opportunities. There may be a cost for getting optimal performance, so it’s a subjective KPI.

Manufacturers can identify areas for improvement and implement changes to optimize the manufacturing process by monitoring and analyzing these key performance metrics. Subject matter experts can easily monitor and analyze these metrics in real-time using AI-powered, no-code manufacturing optimization platforms, allowing for quick identification of areas for improvement and timely implementation of changes.

Manufacturing Performance Management

Once the KPIs have been identified, they need to be measured systematically. Manufacturing performance management involves the measurement and analysis of key performance metrics to improve the manufacturing process. After measurement and analysis, changes should be implemented to optimize the manufacturing process.

To improve manufacturing performance, it is important to establish a baseline for these metrics and set goals for improvement. Regular monitoring and analysis of these metrics can help identify areas of improvement and opportunities for optimization.

With an AI-based manufacturing optimization platform, subject matter experts can easily monitor and analyze these metrics without the need for data science expertise. Such a platform can provide real-time monitoring of manufacturing performance metrics, allowing for quick identification of areas for improvement and timely implementation of changes.

How Vanti Can Help Improve Manufacturing Performance

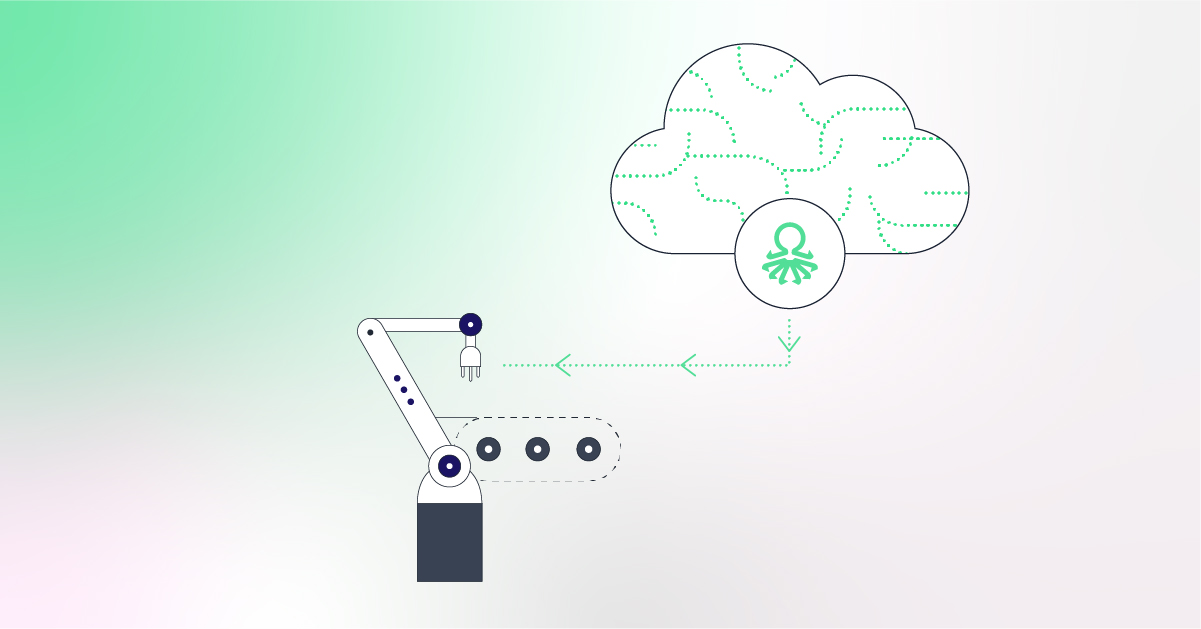

Vanti’s AI-powered no-code platform offers several solutions to improve manufacturing performance without requiring subject matter experts to learn data science. Vanti’s visual defect detection, early quality forecast, and process optimization can help keep equipment speed at the optimum levels. Let’s try to understand how.

Visual Defect Detection:

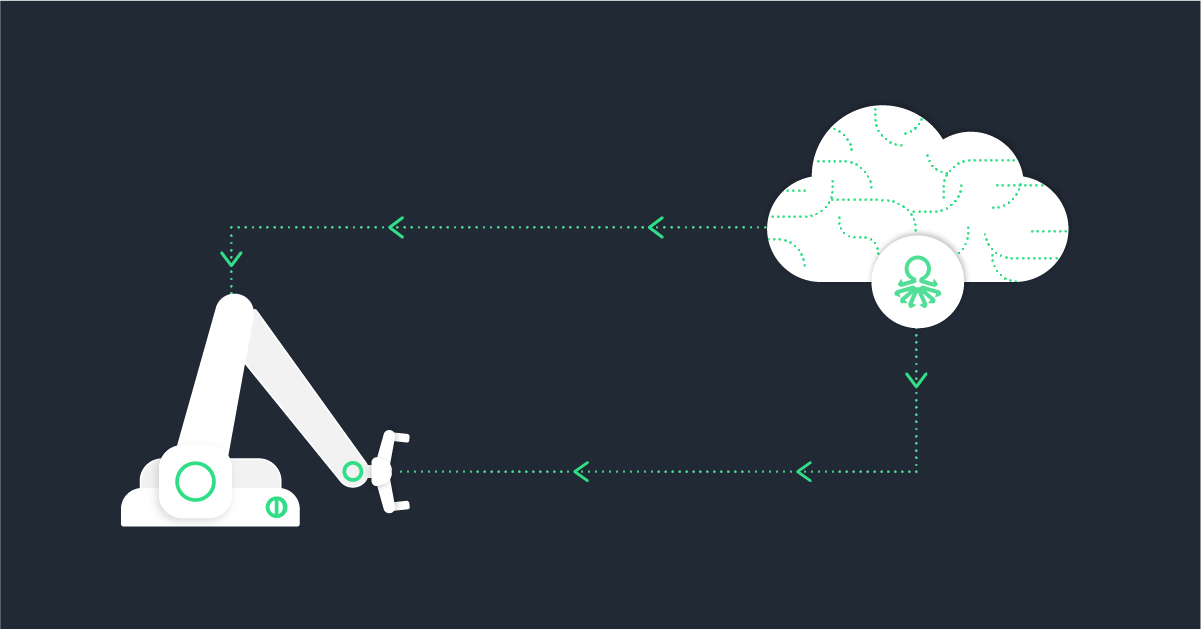

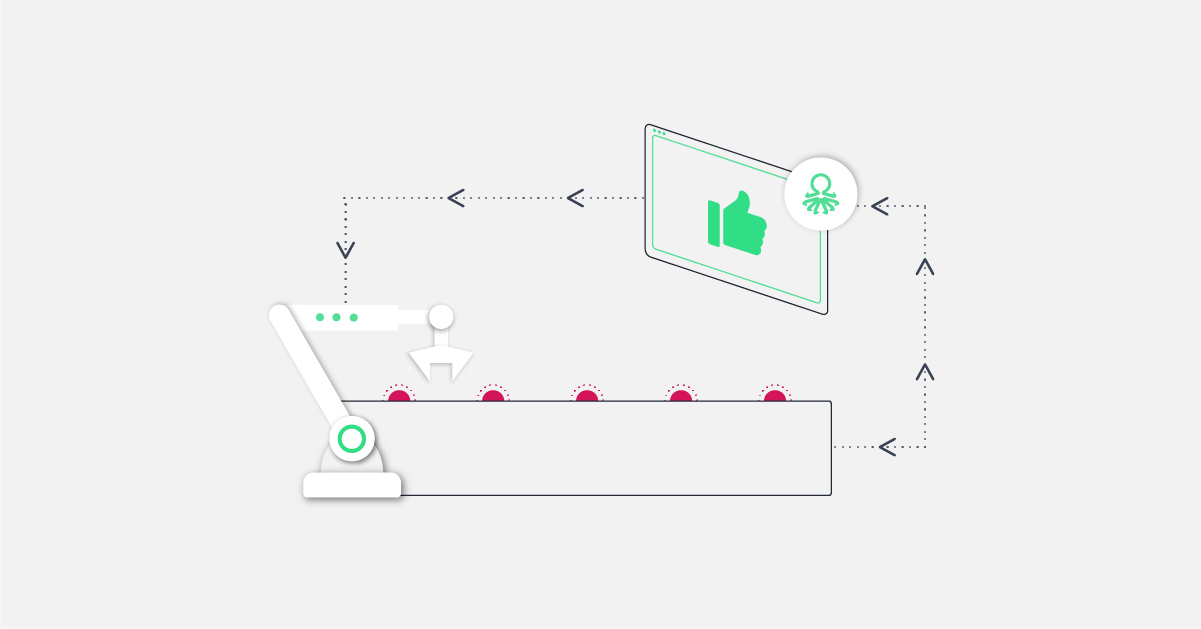

Utilizing machine learning, Vanti’s visual defect detection system powered by AI can detect and pinpoint defects in real-time, empowering manufacturers to detect and address quality issues early on during the production process. This capability helps to minimize waste and maximize productivity, ultimately leading to enhanced operational efficiency.

Early Quality Forecast:

Vanti’s platform can also detect flaws in production in real-time and make accurate quality predictions. As a result, manufacturers can foresee and prepare for quality issues in advance, allowing for proactive alterations and the avoidance of quality problems. As a result of receiving early warnings, manufacturing facilities can cut down on waste and boost output.

Process Optimization:

In addition, Vanti’s process optimization solution uses machine learning to analyze manufacturing data and identify areas for improvement. This allows manufacturers to optimize workflows, reduce waste, and improve efficiency.

By utilizing Vanti’s platform, subject matter experts can also positively impact equipment speed, which improves the OEE metric. Armed with Vanti’s AI-powered capabilities, they can quickly identify areas for improvement and implement changes to optimize manufacturing performance without requiring data science expertise. Vanti’s AI-powered solutions can help manufacturers improve productivity, reduce waste, and increase quality, ultimately leading to better manufacturing performance.

Examples of Improving Manufacturing Performance in Different Industries

As expected, every industrial manufacturing vertical can benefit from manufacturing performance improvement mindset. Listed below are a few instances of how various industries can enhance manufacturing performance:

Consumer Packaged Goods (CPG):

CPG manufacturers can lower expenses while improving product quality by putting visual defect detection systems in place. This technology uses cameras and image processing software to quickly identify and remove defective products as they move down the production line, reducing waste and improving customer satisfaction. By leveraging visual defect detection, CPG manufacturers can also identify areas for process improvement, leading to better overall manufacturing performance. Additionally, analyzing patterns in defects can help manufacturers to optimize their production processes and reduce costs associated with rework and scrap.

Automotive:

Manufacturers can improve the quality of their products by implementing statistical process control (SPC) techniques. SPC involves monitoring and controlling the production process to ensure that it meets specific quality standards. By analyzing data on product defects and variations in production, manufacturers can identify areas where improvements are needed and make changes to the process to reduce defects and improve overall quality. For example, a car manufacturer might use SPC to monitor the dimensions of critical parts during production and adjust the process to ensure that they meet the required specifications. This can help to reduce the number of defects and improve the reliability and safety of the finished product.

Food and Beverage (F&B):

F&B manufacturers can leverage advanced analytics and machine learning algorithms to implement early-quality prediction systems. These systems can use sensory data, such as aroma, texture, and flavor, to predict product quality and identify potential issues before they occur. By enabling real-time adjustments, early quality prediction can help manufacturers reduce waste, prevent costly recalls, and improve overall production efficiency. This would allow manufacturers to meet strict regulatory requirements, maintain brand reputation, and provide consistent, high-quality products to consumers.

These are merely a few illustrations of how manufacturing efficiency can be enhanced in various industries. Manufacturers can raise quality, decrease waste, and increase productivity by identifying areas for improvement and modifying the manufacturing method. Subject matter experts can easily monitor and improve manufacturing performance with the aid of Vanti’s AI-powered no-code platform, which will ultimately produce better business results.

Conclusion

Let’s face it: how well a manufacturing company performs in its production process directly affects its success. By tracking and examining important performance indicators like productivity, quality, efficiency, lead time, flexibility, and expense, manufacturers can improve their processes.

Subject matter experts can easily watch and optimize manufacturing performance using Vanti’s AI-powered no-code platform without having to have a lot of data science knowledge. This makes it easier to optimize the production process, which benefits manufacturers’ bottom lines.

By improving their output performance in the areas of productivity, waste reduction, and quality improvement, manufacturers can stay competitive in today’s booming economy. The Vanti platform will make it simpler for manufacturers to achieve these goals, which will boost their bottom line.